Conductive tapes can be classified in several ways:

Conductive tapes are flexible adhesives that conduct current on one or both sides. These tapes are a useful and cost-effective option for electronic assembly, especially in shielding or grounding applications.

Conductive tape offers many advantages over other assembly methods such as soldering or mechanical fastening. Tapes are flexible, easy to apply, and offer better performance in settings with extreme temperatures or frequent vibrations.

At Robert McKeown Company, we offer a full range of conductive tapes for clients seeking these benefits for their electronic assemblies. As a long-time supplier of high-performance electronics materials, we can work with you to determine the best adhesive tape solution for your needs.

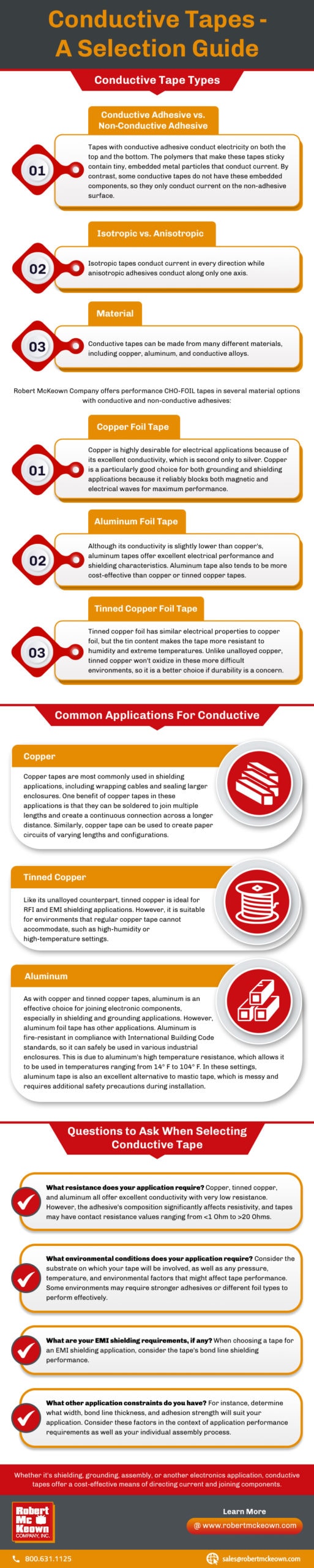

Conductive Tape Types

- Conductive Adhesive vs. Non-Conductive Adhesive. Tapes with conductive adhesive conduct electricity on both the top and the bottom. The polymers that make these tapes sticky contain tiny, embedded metal particles that conduct current. By contrast, some conductive tapes do not have these embedded components, so they only conduct current on the non-adhesive surface.

- Isotropic vs. Anisotropic. Isotropic tapes conduct current in every direction while anisotropic adhesives conduct along only one axis.

- Material. Conductive tapes can be made from many different materials, including copper, aluminum, and conductive alloys.

Robert McKeown Company offers performance CHO-FOIL tapes in several material options with conductive and non-conductive adhesives:

- Copper Foil Tape. Copper is highly desirable for electrical applications because of its excellent conductivity, which is second only to silver. Copper is a particularly good choice for both grounding and shielding applications because it reliably blocks both magnetic and electrical waves for maximum performance.

- Aluminum Foil Tape. Although its conductivity is slightly lower than copper's, aluminum tapes offer excellent electrical performance and shielding characteristics. Aluminum tape also tends to be more cost-effective than copper or tinned copper tapes.

- Tinned Copper Foil Tape. Tinned copper foil has similar electrical properties to copper foil, but the tin content makes the tape more resistant to humidity and extreme temperatures. Unlike unalloyed copper, tinned copper won't oxidize in these more difficult environments, so it is a better choice if durability is a concern.

Before purchasing conductive tape, it’s important to understand these distinctions to ensure you get the results you’re expecting.

Common Applications For Conductive Adhesives

Conductive tapes have many uses, but the most common involve shielding and grounding. For instance, they are often used to attach EMI and RFI shields to electronic devices. They can also be used to pass current to substrates that cannot be soldered or to create corrosion-resistant ground contacts, among other applications.

Copper

Copper tapes are most commonly used in shielding applications, including wrapping cables and sealing larger enclosures. One benefit of copper tapes in these applications is that they can be soldered to join multiple lengths and create a continuous connection across a longer distance. Similarly, copper tape can be used to create paper circuits of varying lengths and configurations.

Tinned Copper

Like its unalloyed counterpart, tinned copper is ideal for RFI and EMI shielding applications. However, it is suitable for environments that regular copper tape cannot accommodate, such as high-humidity or high-temperature settings.

Aluminum

As with copper and tinned copper tapes, aluminum is an effective choice for joining electronic components, especially in shielding and grounding applications. However, aluminum foil tape has other applications. Aluminum is fire-resistant in compliance with International Building Code standards, so it can safely be used in various industrial enclosures. This is due to aluminum’s high temperature resistance, which allows it to be used in temperatures ranging from 14° F to 104° F. In these settings, aluminum tape is also an excellent alternative to mastic tape, which is messy and requires additional safety precautions during installation.

Questions to Ask When Selecting Conductive Tape

Although all conductive tapes carry current, not every tape is right for every application. To determine the best choice, it’s important to consider an application’s requirements for both electrical and physical performance. To make sure you’re selecting the ideal tape for all of your needs, review the following questions before purchasing a tape:

- What resistance does your application require? Copper, tinned copper, and aluminum all offer excellent conductivity with very low resistance. However, the adhesive’s composition significantly affects resistivity, and tapes may have contact resistance values ranging from <1 Ohm to >20 Ohms.

- What environmental conditions does your application require? Consider the substrate on which your tape will be involved, as well as any pressure, temperature, and environmental factors that might affect tape performance. Some environments may require stronger adhesives or different foil types to perform effectively.

- What are your EMI shielding requirements, if any? When choosing a tape for an EMI shielding application, consider the tape’s bond line shielding performance.

- What other application constraints do you have? For instance, determine what width, bond line thickness, and adhesion strength will suit your application. Consider these factors in the context of application performance requirements as well as your individual assembly process.

As you consider these questions, the experts at Robert McKeown Company can help you evaluate different tapes and select the most appropriate option for your application.

Choose Your Conductive Tape Today

Whether it’s shielding, grounding, assembly, or another electronics application, conductive tapes offer a cost-effective means of directing current and joining components. Robert McKeown Company offers a full catalog of CHO-FOIL tapes featuring corrosion-resistant cloth, performance adhesives, and copper, tinned copper, or aluminum foil surfaces. All of our tapes are lightweight and flexible for easy installation, while still offering excellent strength and durability. Both conductive and non-conductive adhesives are available, depending on client needs.

If you have questions about how conductive tapes could benefit your application, or if you need help selecting the right product for your needs, the team at Robert McKeown Company can help. As a leader in engineered electrical materials for over 70 years, we welcome the opportunity to build lasting relationships with clients from all industries and applications. To get started with our high-performance electronics solutions, contact Robert McKeown or request a quote today.

1 Comment

Dan Nemeth

I am looking for a double sided conductive adhesive tape to apply to a grounding pad and another object. Preferably with a removable peel away paper on both sides of the adhesive.