Loctite Ablestik SSP 2020

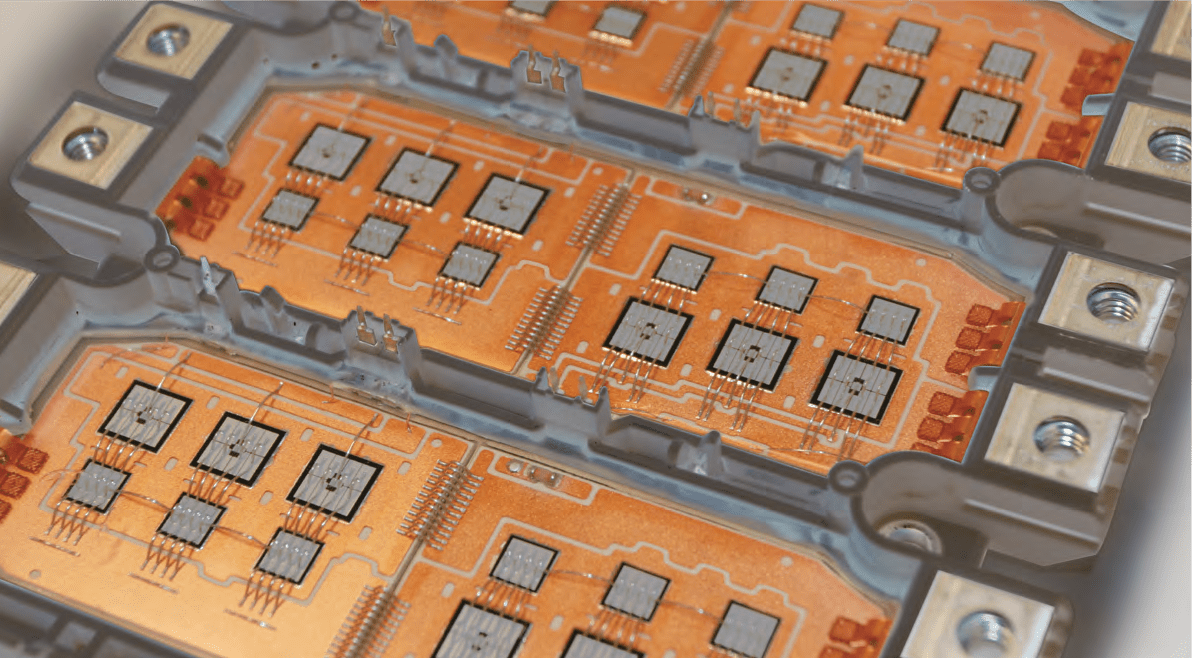

LOCTITE introduces ABLESTIK SSP 2020. An Ag-based material that delivers a robust intermetallic bond between targeted surfaces, the substrate and die, via a pressureless or pressure sintering process. This solution, ideal for high power devices, facilitates much higher thermal and electrical conductivity than traditional die attach adhesives and has performance equivalent or better than solder — all while meeting the stringent requirements of lead-free legislation. The technical staff at the Robert McKeown Company is available to assist you with integration of SSP 2020 into your manufacturing process.

LOCTITE ABLESTIK SSP 2020 is a sintering silver paste die attach adhesive designed for devices requiring elevated thermal and electrical conductivity capabilities. It is formulated to provide high heat transfer generated from power devices. It maintains high adhesion at operating temperatures as high as 260°C. It is stencil printable and syringe dispensable.

- Ideal for high power devices

- Delivers a robust intermetallic bond between targeted surfaces

- Facilitates much higher thermal and electrical conductivity than traditional die attach adhesives

- Provides strong adhesion

- Compatible with current production equipment, high throughput

- 10x thermal cycle & power cycle performance better than solder

SSP 2020 Processing Recommendations

- Pressureless process:

- LDF

- Optimized sintering condition in air: 10ºC/min ramp+1hour at 250ºC

- Lowest sintering temp in air: 200ºC

- Optimized sintering condition in N2: 10ºC/min ramp+1hour at 250ºC

- Lowest sintering temp in N2: 225ºC

- Ag/Cu LDF: N2(

DBC

- Au DBC: 10ºC/min + 1hour at 200ºC

- Ag DBC: 10ºC/min + 1hour at 250ºC

Pressureless Performance Summary

- SSP2020 shows strong joint strength on both Ag/Cu and PPF LDFs

- ~2-3kg/mm2 HDSS for all LDFs & die sizes tested under suitable sintering conditions

- Capable to give good performance under N2 sintering

- SSP2020 shows strong joint strength on both Au and Ag DBC

- ~2-4kg/mm2 DSS under suitable sintering conditions

- Package design is important to reduce the effect of stress

- Thicker die pad(>1mm) and or thinner die give less risk of die back side metal peel off

- A published presentation on a customer’s experience is available

Pressure process

- Drying: 40 minutes @ 120ºC

- Sintering condition on Ag and Au DBC

- Temperature: 250ºC, time: 120 seconds, pressure: 10MPa

- Lower pressure can be used at higher temperature to achieve equivalent results

- Higher pressure can be used at lower temperature to achieve equivalent results

SSP 2020 Pressure Sintering Performance Summary

- SSP 2020 has very dense structure after pressure sintering

- <12% porosity at 10MPa sintering and <5% porosity at 30MPa sintering

- For pressure sintering process, recommended drying conditions of SSP 2020 are 60 minutes at 90°C, 40 minutes at 120°C, or 30 minutes at 150°C

- Lower drying temp gives slightly higher organic residue

- DSC shows that high drying temp may induce partial sintering or growth of particles.

- For DSS and bending performance, Ag DBC gave much better results than Au DBC

- Pressure and sintering temp have the most significant effect on performance.

- Sintering time is important for the samples sintered at lower temp/pressure. 60 seconds tends to give lower performance than 120 seconds and 300 seconds

- Drying conditions have no significant effect for most samples

- DSS and bending test gives clear indication of material performance.

However, they show limitation for the samples sintered at high temperature/pressure. Further peel test will be conducted to fully understand the material performance in the whole temperature/pressure range tested

Summary and process recommendation

- Material properties

- Filler – silver

- Color – silver

- Viscosity (25oC 5rpm) (cp) 15,700

- Thixotropic index 4.6

- Freezing point -97oC

- Shelf life, >120 days @ -40ºC

- Shipping & storage at -40oC

Processability

- Stable work life, > 8 hours at RT

- Robust dispense performance

- Robust stencil print performance

- Open time, > 4 hours (1x1mm die) at RT

- Stage Time, > 8 Hours at RT.

- Pressure-less or pressure assisted sintering

Application assistance and/or samples of Loctite Ablestik SSP 2020 are available through the Robert McKeown Company. Contact us today at 800.631.1125 or sales@robertmckeown.com