Composite Adhesives

When bonding composites, traditional bonding techniques such as mechanical fastening and welding can weaken or damage the composite materials. As such, adhesives have become the ideal bonding agent for joining composites in a wide range of industries. To ensure optimal strength and performance, it’s important to select the right type of composite adhesive for your application. At Robert McKeown Co., Inc., we’ve been delivering high-quality adhesive solutions since 1937. Understanding the various types of composite adhesives as well as their benefits and applications can help you determine the ideal solution for your needs.

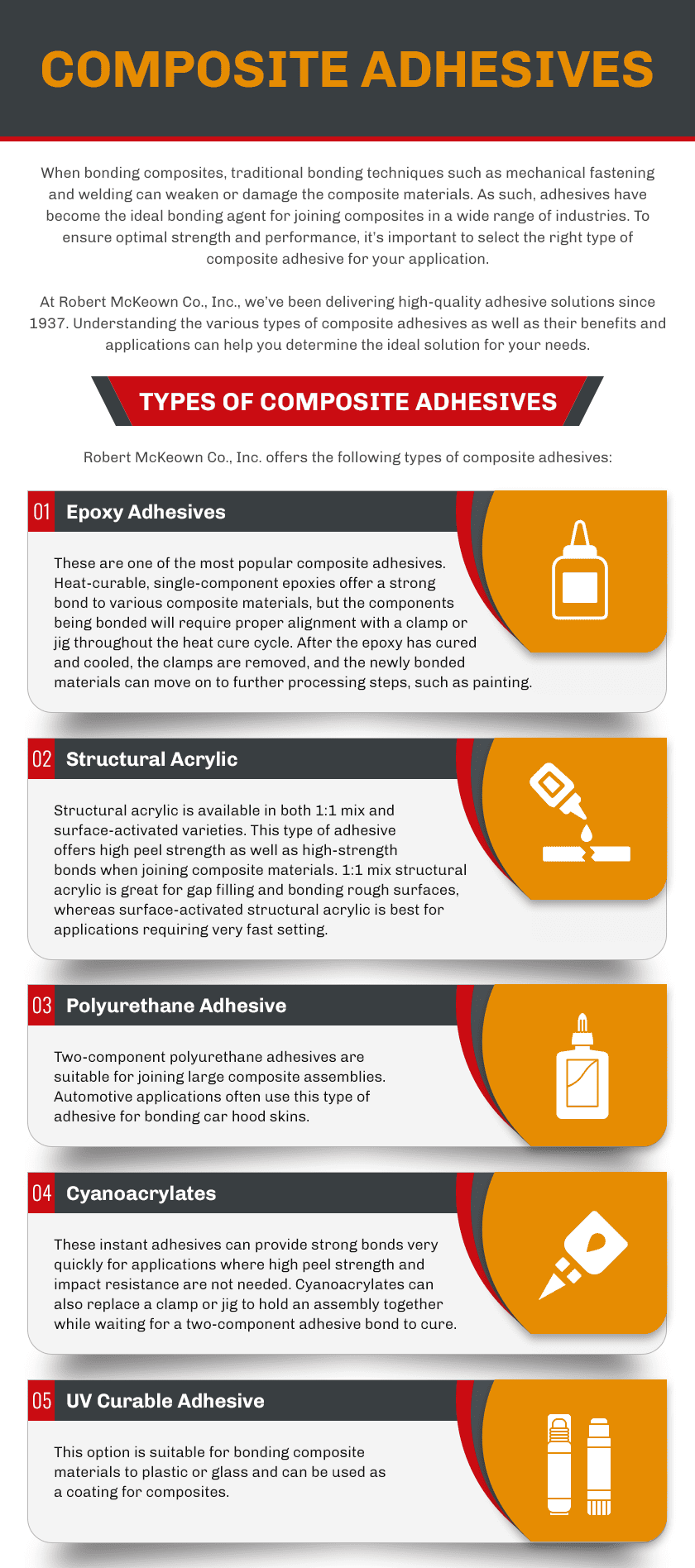

Types of Composite Adhesives

Robert McKeown Co., Inc. offers the following types of composite adhesives:

- Epoxy Adhesives. These are one of the most popular composite adhesives. Heat-curable, single-component epoxies offer a strong bond to various composite materials, but the components being bonded will require proper alignment with a clamp or jig throughout the heat cure cycle. After the epoxy has cured and cooled, the clamps are removed, and the newly bonded materials can move on to further processing steps, such as painting.

- Structural Acrylic. Structural acrylic is available in both 1:1 mix and surface-activated varieties. This type of adhesive offers high peel strength as well as high-strength bonds when joining composite materials. 1:1 mix structural acrylic is great for gap filling and bonding rough surfaces, whereas surface-activated structural acrylic is best for applications requiring very fast setting.

- Polyurethane Adhesive. Two-component polyurethane adhesives are suitable for joining large composite assemblies. Automotive applications often use this type of adhesive for bonding car hood skins.

- Cyanoacrylates. These instant adhesives can provide strong bonds very quickly for applications where high peel strength and impact resistance are not needed. Cyanoacrylates can also replace a clamp or jig to hold an assembly together while waiting for a two-component adhesive bond to cure.

- UV Curable Adhesive. This option is suitable for bonding composite materials to plastic or glass and can be used as a coating for composites.

Advantages of Composite Adhesives

Because of their many advantages, composite adhesives have grown in popularity for various design and manufacturing applications. With recent technological advances, these substances can meet the same high-strength requirements as traditional mechanical attachments and rivets while providing a wide range of other specific, often customizable benefits, including:

- Aesthetic final appearance without costly finishing work

- Sealing capabilities

- Galvanic corrosion prevention between two dissimilar metals

- Ability to join two different materials

- Even stress distribution in bond joints

- Vibration absorption

- Excellent for bonding thin substrates

Depending on your particular application needs, composite adhesives are available in various formulations to deliver superior performance, toughness, and durability under a wide range of environmental conditions, including high-temperature applications. Adhesive films can be co-cured with composites, are suitable for bonding small or large parts, allow for precise adhesive application, and can often be used with automated equipment.

Typical Applications for Composite Adhesives

Robert McKeown Co., Inc.’s composite adhesives are ideal for a wide range of industrial and commercial applications in industries such as aerospace, electronics, automotive, construction, energy, and more. Specific applications include:

- Wind turbine blades

- Bonding honeycomb sandwich panels

- Aircraft interior cabin

- Medical prosthetics and orthopedic devices

- Storage tanks

- Carbon fiber vehicles

- Racing cars

- Sports equipment

- Metal-to-metal sandwich structures

- Perforated panel assembly

- Pipeline repair

- Aerospace components

Composite Adhesives From Robert McKeown Co., Inc.

Compared to traditional fasteners and joining techniques, composite adhesives offer numerous benefits that make them a great choice for bonding composite materials. At Robert McKeown Co., Inc., we are a leading distributor of high-quality adhesive and sealants for a wide range of applications and industries. Dedicated to constant innovation and improvement, we can deliver a composite adhesive solution to meet your particular application requirements to ensure optimal performance and bond strength.

For more information about our composite adhesives, or for help determining which adhesive option is best for your needs, contact the experts at Robert McKeown Co., Inc. or request a quote today.