EMI in the Aerospace Industry

EMI, or electromagnetic interference, is a massive concern in the aerospace industry due to the disruptions it can cause to crucial sensitive electronics utilized in numerous aerospace-intensive operations. EMI is a signal from an external source that causes data corruption, system malfunctions, and even total failure, which aerospace components are incredibly sensitive to. Therefore, preventing EMI from affecting essential electronics is imperative. Fortunately, EMI solutions are employed to block or shield this destructive signal from causing more interference with surrounding devices.

Common EMI Issues In the Aerospace Industry

The aerospace industry faces numerous challenges regarding reliable and robust communication systems and other avionics equipment. One of the most significant problems this industry continues to battle is EMI, which causes aerospace electronic equipment to degrade and malfunction.

Constant exposure to EMI can prevent vital equipment from functioning properly, affecting the rest of the aircraft’s operation. It’s a huge nuisance and inconvenience that can affect the level of safety an aircraft can provide to its passengers. Unfortunately, there are many other EMI Aerospace issues faced by this demanding industry, including:

- EMI blocks and disrupts signals that are imperative in communication systems.

- EMI affects navigation radars and cockpit radio signals

- EMI may be the reason for erratic flight deck indications and causing the plane to fly off-course

Plenty of airborne devices can facilitate EMI inside an aircraft. Apart from natural sources like lightning and solar flares, man-made sources are also the suspected culprit. Examples include:

- Laptop computers

- Smartphones

- Electronic games or video consoles

- Electronic toys

That said, using high-quality EMI solutions has become necessary in the aerospace industry to protect vital avionic electronics systems utilized inside the aircraft. The proper EMI shielding products can eliminate these dangers and improve aerospace-related projects.

EMI Solutions For the Aerospace Industry

RFI/EMI Shielding

Electronic interference in aircraft comes from fly-by-wire systems, safety systems, and even passenger electronic devices. To operate correctly, the aircraft, its communications equipment, safety equipment, missile systems, and launchers all need shielding. RFI-shielding solutions help make aircraft less susceptible to damage from lightning strikes. EMI-shielding gaskets protect mission-critical missile systems from radio frequency interference.

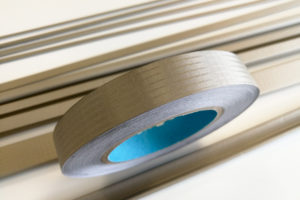

Aerospace Adhesive Tapes

Aerospace adhesive tapes are used in a variety of ways to mask temperature, keep out moisture, and create essential bonds. Some of the most important uses for aerospace adhesive tapes include:

- Anti-vibration and friction for window shades

- Protecting hoses, wires, and cables

- Sealing cargo area with flame-retardant tapes

- High temperature masking up to 500° F

- Carpet attachment to floors

- Surface protective products

- Moisture barrier to secure seams in air conditioning, duct, and air handling systems

Liquid Silicone Rubber

Outstanding endurance levels for stress and temperature make liquid silicone rubber useful for a wide range of purposes in the aerospace and aviation industries. Essential in both interior and exterior applications to seal, insulate, and protect a wide variety of parts, examples of liquid silicone rubber applications include:

- Door Seals

- Window Seals

- HVAC Seals

- Thermal Insulation

- Engine Gaskets

- Vent Ducts

- Instrument Panel Seals

- Vibration Dampening

EMI Solutions For Aerospace by Robert McKeown

As leaders in EMI solutions, our products are specially designed and developed to address the problems commonly found in the aerospace industry. We aim to deliver high-performance shielding products against EMI aerospace interference to guarantee the success of your projects.

If you want to know more about our EMI shielding solutions, don’t hesitate to contact us today; one of our experts will provide all the information you need. Request a quote, and we can discuss a cost-effective solution tailored to your needs!