About Robert McKeown

Robert McKeown has been a family-owned, world-class distributor and fabricator of high-performance EMI materials in the industry since 1937. We utilize superior EMI technologies to produce unparalleled results for our clients, resulting in our outstanding reputation as a trusted source of reliable and high-quality materials, specializing in electronic assembly, circuit protection, thermal management, and EMI/ESD suppression products.

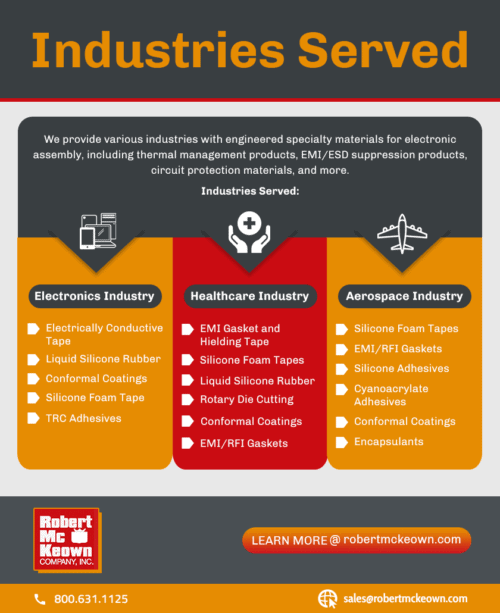

We provide various industries with engineered specialty materials for electronic assembly, including thermal management products, EMI/ESD suppression products, circuit protection materials, and more. Our common industries served include:

Electronics Industry

We offer a wide range of isolation, insulation, and electronic tapes, as well as grounding materials, sealants, and more, which are fabricated with our unique EMI technology. Our solutions for the electronics industry ensure high-performance electronic assemblies that function without failure or interruption. Some of our most popular products for the electronics industry include:

- Electrically Conductive Tape. Electrically conductive tape guides electrical energy to the appropriate pathway, making it ideal for EMI shielding applications and providing reliable grounding.

- Liquid Silicone Rubber. This variety of rubber is resistant to skin chemicals and oils, temperature changes, and physical wear and damages from constant touching. This product makes it an ideal choice for regularly used electrical products, including medical electronics.

- Conformal Coatings. Conformal coatings cover printed circuit boards (PCBs) to protect their sensitive components.

- Silicone Foam Tape. With high-temperature stability, resiliency, and easy application, silicone foam tape is used in various electrical applications to seal out dust, water, and more.

- TRC Adhesives. These UV-curable adhesives harness the best features of traditional silicone but present enhanced strength, higher heat resistance, less shrinkage, and better performance. Common electrical applications include housing assemblies, sensors, lighting modules, and more.

Healthcare Industry

EMI shielding materials play an essential role in protecting various electronic devices, including medical devices used throughout the healthcare industry. Some of the most common products and services we provide for the healthcare industry include:

- EMI Gasket and Shielding Tape. EMI shielding materials prevent strong external sources from interfering with surrounding electronics. Our EMI gasket and shielding tape products protect life support systems, pacemakers, monitoring devices, and other medical equipment from harmful EMI.

- Chemical Resistant Adhesive. Our adhesives protect against water, sterilization chemicals, acids, solvents, alcohols, fuel, and other potentially corrosive materials used within the healthcare industry.

- Silicone Foam Tapes. Safe for skin contact, silicone foam tapes are frequently used for direct-contact applications, such as the attachment of grounding pads, mounting electrodes, and other devices to the patient’s skin.

- Liquid Silicone Rubber. Unlike most other rubbers, silicone remains liquid at room temperature and only hardens into a solid when exposed to high heat. It also remains stable over a range of temperatures and is resistant to most chemicals, making it safe and easy to sterilize for medical applications.

- Rotary Die Cutting. Rotary die cutting provides components with high levels of precision and detail, making it ideal for creating a wide range of medical parts.

Automotive Industry

The automotive industry relies on durable products that can withstand extreme weather conditions and high temperatures while also providing good electrical properties, chemical resistance, and more. At Robert McKeown, we offer the following products and services for the automotive industry:

- Rotary Die Cutting. Rotary die cutting offers a quick way to produce high-quality automotive components in large production runs. This method is commonly used to create sensitive navigation components and heat shields.

- Liquid Silicone Rubber. Liquid silicone rubber can withstand extreme weather conditions and stretching, making it ideal for various automotive applications such as windshield wipers, LED headlights, airbag coating and sealing, wiring harness components, and more.

Aerospace Industry

Through our cutting-edge EMI aerospace products, we have supported this demanding industry by providing crucial materials used to protect aircraft components, communication systems, and satellite technology against radiofrequency and electromagnetic interference.

These specially developed products can prevent EMI from interfering with highly critical aerospace technologies like cockpit radios and radar signals. They are also designed to work against extreme temperatures and intense vibrations, ensuring the protection of your equipment. The main products and services we offer as part of our EMI aerospace solutions include:

- EMI Gasket and Shielding Tape. Our EMI/RFI-shielding materials can prevent aircraft damage due to lightning strikes. Gaskets are also paramount in protecting mission-critical missile systems from radio frequency interference.

- High Temperature Film. High temperature adhesive tapes are necessary in excessively high temperatures. These can also provide much-needed electrical insulation while effectively withstanding temperatures up to 500°.

- Silicone Foam Tape. These specially designed tapes protect wirings, eliminate friction and vibration for window shades, and seal cargo areas.

- Liquid Silicone Rubber. This versatile material has incredibly high endurance against stress and temperature. It’s utilized in a wide range of aerospace parts, whether interior or exterior. Liquid silicone rubber is ideal for door seals, engine gaskets, vent ducts, and more.

Robotics Industry

The robotics industry also experiences EMI issues that can impact the performance of these advanced machines. To help mitigate these issues, we utilize state-of-the-art EMI technology to create EMI robotics shielding products that can reduce equipment failure while enhancing their performance and durability.

With our meticulously engineered EMI robot shielding materials, manufacturers can freely and successfully put their conventional ideas into action to advance the capabilities of modern robotics. We have the following EMI robotics solutions ready for any application:

- Gap-Filling Thermal Interface. These materials are designed for efficient heat transfer while deforming gaps to address flatness problems and ensure compliance.

- EMI Gaskets and Tapes. Apart from being used as EMI shielding materials, gaskets also function as an environmental seal. We offer custom molded gaskets to prevent moisture, dust, and other debris from penetrating the robot’s interior parts.

- Conformal Coatings. Dependable and long-term protection for robotic substrates, whether made from composite or plastic materials. Our coatings provide a substantial barrier resistant to dust, humidity, moisture, chemicals, and corrosive agents, protecting robots during chemical-intensive operations.

- Silicone Foam Tapes. These tapes offer exceptional sealing capabilities for rods, robotic arms, and more with their ability to suppress vibrations and withstand high temperatures. They are easy to install and remove when necessary without leaving any adhesive residue.

Industrial Machinery Industry

Our selection of EMI suppression products is widely employed in countless industrial machinery to streamline the production process while improving overall conditions. Using our EMI shielding products, automated industrial machinery becomes less susceptible to electromagnetic interference. Therefore, the result is better productivity, efficiency, and reduced downtime while extending the lifespan of the equipment. Some of the EMI automation materials we specialize in are as follows:

- Epoxy Encapsulant. Potting and encapsulation products are highly recommended to protect your machine’s PCB by elevating its mechanical strength, which protects against shock and reduces vibrations.

- Conformal Coatings. Industrial machines rely on the properties of conformal coatings to protect the surface from degradation while operating in various harsh and stressful environmental conditions.

- Thermally Conductive Tapes. Thermal energy becomes impossible to manage and can destroy parts and components in automated industrial machinery. Preventing premature failure and maintaining lifespan is achievable with our thermal management products.

- Electronic Tapes. Electrically conductive tapes are necessary to improve the traction of industrial machines, delivering superb electronic isolation and functioning well under extreme mechanical stress.

Technology and Automation Industry

We have an advanced proto-fast design center responsible for delivering optimized efficiency while accelerating innovation in the technology sector. Since numerous industries utilize ingenious electronic advancements to support their growth and operations, EMI technologies are crucial for a more streamlined workflow. Some products that can help in the acceleration of IoT, automation, and smart devices include:

- Electronic Tapes. Electronically conductive tapes are outstanding barriers that prevent short circuits, sparks, and potential hazards that may occur during operations.

- Thin Interface Thermal Insulators. Superior thermal, electrical, and mechanical properties are necessary to ensure semiconductors in automated equipment are not damaged by heat.

- Shielding Tapes. Shielding tapes can protect a variety of electronic displays, input/output devices, and touch screens from EMI interference while also preventing the emission of interference signals. It ensures that automated equipment operates smoothly without interference from external sources.

High-Performance Electronics Material by Robert McKeown

Regardless of your industry, choosing the right high-performance EMI material will enhance performance and drive success to your projects. At Robert McKeown, we have produced industrial-standard EMI shielding solutions for many years, allowing us to remain at the forefront of innovation

With a vast range of EMI technology and solutions, we have the expertise to address any EMI challenges your industry is experiencing. Contact us today if you have any questions about our products and services. You may also request a quote, and our team will develop a cost-effective solution based on your specific needs.