Thermal Interface Materials | Robert McKeown

Sensitive systems must adhere to strict temperature requirements to operate safely and efficiently. Many electronic devices utilize heat sinks and fans to maintain cool temperatures, but thermal interface materials (TIMs) also play a crucial role in helping dissipate heat.

As the functionality of electronic devices increases, they generate more heat. Reliability and peak performance depend on effective thermal management solutions to allow operation within required specifications. Heat-dissipating materials like TIMs help maintain the correct temperature limits and are a key component of thermal management systems.

TIMs fill small gaps or irregularities between two surfaces to help transfer heat between them more effectively, as such gaps can significantly reduce heat transfer efficiency. Improving thermal conductivity, TIMs can be made of various materials, such as grease, silicone, adhesive, or pads. Each material has unique properties and offers various benefits for its intended application.

Commonly used in the automotive, aerospace, electronics, and energy production industries, thermal management materials are crucial to ensuring safe, uninterrupted operation. Learn more about the types of thermal interface materials, their common applications, and how to choose the right one based on your application and requirements.

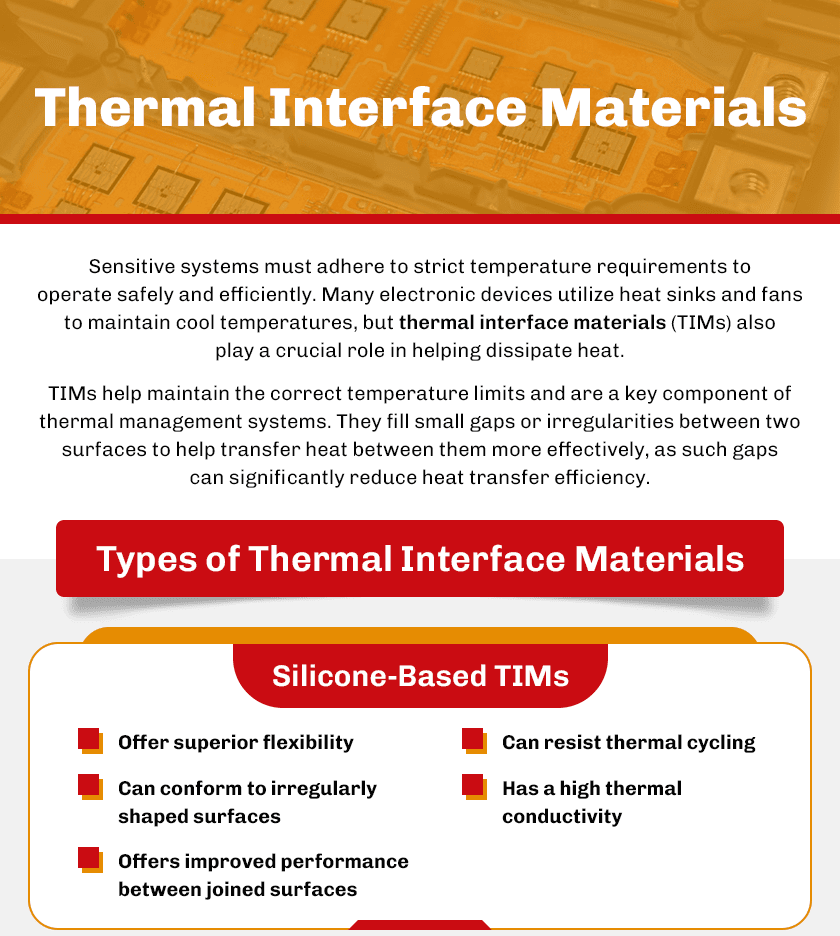

Types of Thermal Interface Materials

Choosing the proper thermal management material depends on your specific requirements and application. The following heat-dissipating materials are examples of the common types of TIMs available on the market.

Silicone-Based TIMs

Silicone-based TIMs offer superior flexibility and can conform to irregularly shaped surfaces, making them a popular choice in many industries. This thermal management material has high thermal conductivity and can resist thermal cycling, offering improved performance between joined surfaces.

Grease-Based TIMs

Grease-based TIMs have a low viscosity, high thermal conductivity, and are an ideal choice for applications where space is limited. This type of TIM is also suitable for instances where controlling thickness and distribution is important. They do not require a cure cycle and are often used in heat sinks and electronic assembly applications. While very conformable, grease-based TIMs require drying time, which may limit the operator’s ability to maintain this type of thermal management material over time.

Pad-Based TIMs

Pad-based TIMs typically consist of graphite or other heat-dissipating materials that have high thermal conductivity. These TIMs are beneficial in applications such as power generation and electronics. Customizable and electrically conductive, graphite pad-based TIMs come in a wide variety of options, offering benefits such as:

- Low deflection force

- High tackiness to reduce contact resistance

- Effective at temperatures up to 200 °C

Adhesive-Based TIMs

This versatile thermal management material is known for its ease of application and bonding strength. It is an optimal choice for the automotive, electronics, and other industries.

As specialized adhesives, these TIMs can securely hold in place while effectively handling heat transfer. Adhesive-based TIMs are typically available in sheets, tapes, curing fluids, or other pressure-sensitive styles. Each product offers unique mechanical and adhesive properties, ranging from permanent adhesion to easily peeling away. Some adhesives have a soft texture, while others can be rubbery.

Industry Applications

Some of the industry applications for TIMs include but are not limited to:

- Electronics: Used in a vast array of products such as smartphones, computers, and other electronic devices, electronic TIMs transfer heat from the GPU or CPU to the heat sink, which dissipates heat to the air in the surrounding environment.

- Automotive: TIMs can transfer heat from the engine to the cooling system, helping to ensure the engine operates at the proper temperature. These thermal management solutions play a critical role in optimizing the longevity and performance of automobiles.

- Aerospace: Aerospace TIMs are used in avionics systems to transfer heat from electronic components to the heat sink. They also effectively transfer heat from the engine to the cooling system.

- Energy: TIMs are beneficial in power transmission and generation systems to transfer heat from generators to cooling systems. They can also be used to transfer heat from solar panels to cooling systems in solar power systems.

- Medical Device: Used to transfer heat from various electronic components to heat sinks, TIMs in medical devices help ensure the device operates at the proper temperature, which is crucial for protecting patient health and operator safety.

Choosing Thermal Interface Material

There are several important factors to consider when selecting a thermal management material, some of which include:

- Thermal Conductivity: This factor determines the ability of a thermal management material to transfer heat in a given application.

- Viscosity: Viscosity measures how thin or thick a material is and determines its ease of application. Typically, the TIM must adhere to both the fluidity and viscosity range required for an application to ensure proper functionality.

- Hardness: A gap in any material can impact its thermal properties. A hard material will fill in gaps more efficiently, preventing vibrations. A softer material is better suited for components that do not need micro-gap fills and are already secured. TIM hardness can be measure using ASTM D2240-00 and Shore durometer.

- Thermal Resistance: Thermal resistance is the measure of the temperature difference between two materials regarding heat flow. The higher the thermal resistance, the more heat the system retains. A lower thermal resistance has better thermal transfer properties.

- Compliance: This factor pertains to how well a TIM can conform to irregular surfaces and is particularly important when those surfaces are not completely flat.

- Pressure: Thermal materials have varying thermal conductivity based on whether they are under high or low pressure.

- Durability: Durability is defined as how well a TIM can withstand environmental factors such as thermal cycling. This consideration is important especially if the application will expose the TIM to harsh conditions and high temperatures.

- Operating Temperature Range: This is the temperature range where electronic devices function. The TIM needs to be able to operate within these ranges.

- Ease of Application: This determines how easily a TIM is applied. Ease of application is important to consider for applications that require frequent reapplication or replacement. Thermal materials must be easy to apply, especially in applications with high-volume production demands.

- Surface Finish: Gaps between surfaces will lower heat transfer capabilities since air is not a good thermal conductor. Surface finish is determined by the imperfections or roughness of the mating surfaces. For example, a smoother surface finish will leave less air between the surfaces, improving overall heat transfer.

Thermal Interface Materials by Robert McKeown Company, Inc.

TIMs play an essential role in a wide variety of industries, including electronics, automotive, aerospace, energy, and medical device manufacturing. Thermal management materials are available in a vast range of styles with unique properties and benefits to meet the demands of any application.

Since 1937, Robert McKeown Company, Inc. has been a leading fabricating distributor of high-performance engineered materials. We are a reliable resource for high-quality thermal management solutions suitable for a wide range of applications. We can help you select a TIM to effectively control heat dissipation and enhance device performance.

Contact us to discuss the requirements of your specific application.