A conformal coating is a polymeric film that manufacturers coat onto a printed circuit board (PCB) in a thin layer to safeguard the board and its components from corrosion and harsh environmental conditions. Manufacturers generally apply conformal coatings in the 25-250µm range to minimize corrosion degradation in metalized regions of the PCB, such as solder joints, electronic component leads, and exposed traces. The film increases the life span of the PCB by adhering to the layout of the board and its parts. While these coatings are lightweight, they retain and increase a product’s dependability, offering reliable performance and larger gradients of voltage without taking up much space in a component.

In addition to providing overall system protection from abrasion or vibration, coatings for electrical parts defend against failure resulting from temperature extremes or fluctuations, moisture and humidity, dielectric concerns, and contaminants like dust, vapor, or fungi. This additional protection is essential to ensure optimum performance over time as advanced electronic components are exposed to harmful conditions.

Choosing the right material for an application allows the proper coating to reduce the influence of electrical impulses on the circuit and increase its efficiency in specific environments. At Robert McKeown Company, Inc., our team is here to help you find the right conformal coating for your application in this guide of common types and coating and curing methods.

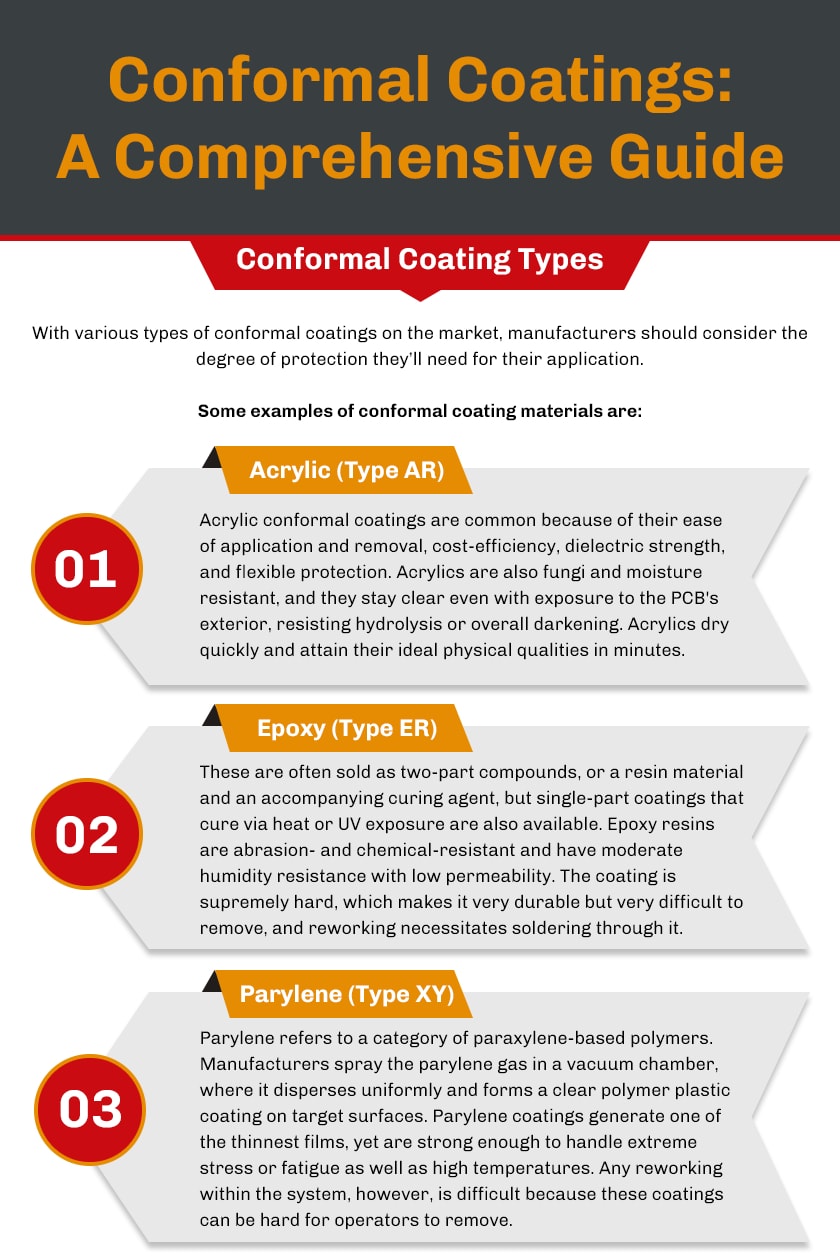

Conformal Coating Types

- Acrylic (Type AR). Acrylic conformal coatings are common because of their ease of application and removal, cost-efficiency, dielectric strength, and flexible protection. Acrylics are also fungi and moisture resistant, and they stay clear even with exposure to the PCB's exterior, resisting hydrolysis or overall darkening. Acrylics dry quickly and attain their ideal physical qualities in minutes.

- Epoxy (Type ER). These are often sold as two-part compounds, or a resin material and an accompanying curing agent, but single-part coatings that cure via heat or UV exposure are also available. Epoxy resins are abrasion- and chemical-resistant and have moderate humidity resistance with low permeability. The coating is supremely hard, which makes it very durable but very difficult to remove, and reworking necessitates soldering through it.

- Parylene (Type XY). Parylene refers to a category of paraxylene-based polymers. Manufacturers spray the parylene gas in a vacuum chamber, where it disperses uniformly and forms a clear polymer plastic coating on target surfaces. Parylene coatings generate one of the thinnest films, yet are strong enough to handle extreme stress or fatigue as well as high temperatures. Any reworking within the system, however, is difficult because these coatings can be hard for operators to remove.

- Polyurethane (Type UR). Polyurethane or urethane coatings have high chemical and humidity resistance, particularly as compared to acrylic resins. While flexible polyurethane resins are simple for manufacturers to apply and have a long pot life as they hold up well to abrasion, they might take a long time to cure to obtain the full or maximum cure and can be difficult for operators to remove.

- Silicone (Type SR). Silicone provides a clear, soft, flexible coating that is resistant to moisture, chemical or salt corrosion, temperature ranges, and vibration. Another unique characteristic is that silicones can coat LED lights without dimming them or altering the light's color. Silicones are not solvent-soluble, however, and manufacturers must apply them with a special solvent and remove them using chemical strippers. Also, silicone is not highly resistant to abrasion.

- Water-based. Conformal coatings with a water base have low solvent emissions and use evaporation for the curing process. These coatings are safe, then, for users as well as the environment. They are simple for manufacturers to apply with standard equipment, and manufacturers can also hybridize them with other materials to improve performance. Typical water-based coatings already provide adequate resistance to chemicals.

- Hybrids. As the name suggests, manufacturers can combine various bases to achieve coating options with specific properties. For example, different coating combinations provide better protection for PCBs against high temperatures or corrosive chemicals.

How to Apply Conformal Coatings

It’s crucial to choose the correct application procedure for a selected coating, and manufacturers can pick from manual or automated coating options. In manual spraying operations, workers will use a handheld aerosol can or a spray gun to apply the coating to a component. As with most manual processes, it is slower and best suited to smaller production runs, prototypes, or those necessitating a smaller budget.

For automated spraying processes, manufacturers can program a spray system to transport the PCB over a conveyor belt and spray the coatings on a component from the machinery’s spray head. It is a much faster and more effective way to spread conformal coatings and allows for larger production runs. In both manual and automated cases, manufacturers should apply the coatings in well-ventilated areas.

Some of the other techniques with which manufacturers can apply conformal coatings include:

Brush coating.

Brush coating is the simplest and cheapest method. As the name indicates, the user manually applies the chosen wet coating to particular parts of the PCB using a brush. It is an effective technique for mending or touching-up boards. While it is a low-cost process, it does necessitate a significant amount of physical effort. It is also extremely variable dependent on material consistency and user competence. Small manufacturing runs are best suited to this strategy.

Dip coating.

This is a standard conformal coating method for high-volume production. For this technique, manufacturers soak the circuit board in the conformal coating solution for a short time and then remove it. The speed and duration for which users dip and withdraw the board as well as the coating viscosity all play a role in film development.

Selective coating.

Selective coating utilizes an automated conformal coating technology that applies the coating to highly exact regions on the circuit board using programmed robotic spray nozzles. This method can reduce the requirement for masking in high-volume production.

How Long Does It Take for Conformal Coating to Dry?

The length of time that it takes for conformal coatings to dry is dependent on the thickness and composition of the coating, but also on the method the manufacturer uses to cure the coating. Manufacturers can accomplish curing with:

- Moisture. In this method, conformal coatings use moisture from the air to cure the resin, as humidity typically speeds up the curing process. In urethane and silicone systems, the solvents will evaporate, and the remaining moisture acts with the resin to cure the coating within as little as a few minutes, with full-cure at a few days. Given the evaporation step of the process, this method is often used with other curing techniques like evaporation curing.

- Evaporation. This curing type pairs well with moisture curing or other curing methods. With the evaporation of the liquid carrier into the air, the resin coating material is what remains, and the coating will continue to cure over several days. However, users can handle the coated circuit boards within about an hour of completing the coating process.

- UV light. Coatings that manufacturers treat with UV light have a very high throughput. There are no carrier solvents in these systems, and so they are completely solid. The UV light only cures the sections of the PCB that the light hits, however, meaning that a supplementary curing mechanism is necessary for any areas that fall in shadow or lay beneath the top surface receiving the light. The lit surface will cure almost immediately, but anything not in the direct light could take days to complete the curing process.

Heat. In single or multi-part systems, heat curing methods act as a complement to moisture, evaporative, or UV curing techniques when those techniques alone might be unsuccessful in offering specific protection characteristics. Heat will induce the system to polymerize, shortening the cure time to as little as 20 minutes. With this method, it is important to ensure that the temperature does not exceed what is safe for the electrical components of the PCB.

Conformal Coatings From Robert McKeown

Overall, the task for which a manufacturer requires coating materials and the level of protection a coated component needs to achieve determine the proper coating material and technique for production. At Robert McKeown, we have been distributing high-quality, superior-performance conformal coatings, potting compounds, and other engineered materials since 1937. Our family-owned company believes strongly in customer service, and so our experienced and knowledgeable staff works with our clients to find the coating or potting solutions that fit a client’s specific needs from a wide array of protective options, including silicone pottings and encapsulant gels. As an ISO 9001:2015-certified company, we at Robert McKeown are committed to excellence.

For any questions about the conformal coatings we supply, contact us and our experienced technical support staff will be happy to assist you. If you are ready to begin your project, request a quote today.