Month: Aug 2019

Which Electrical/Electronic Tape Is Right for Your Application?

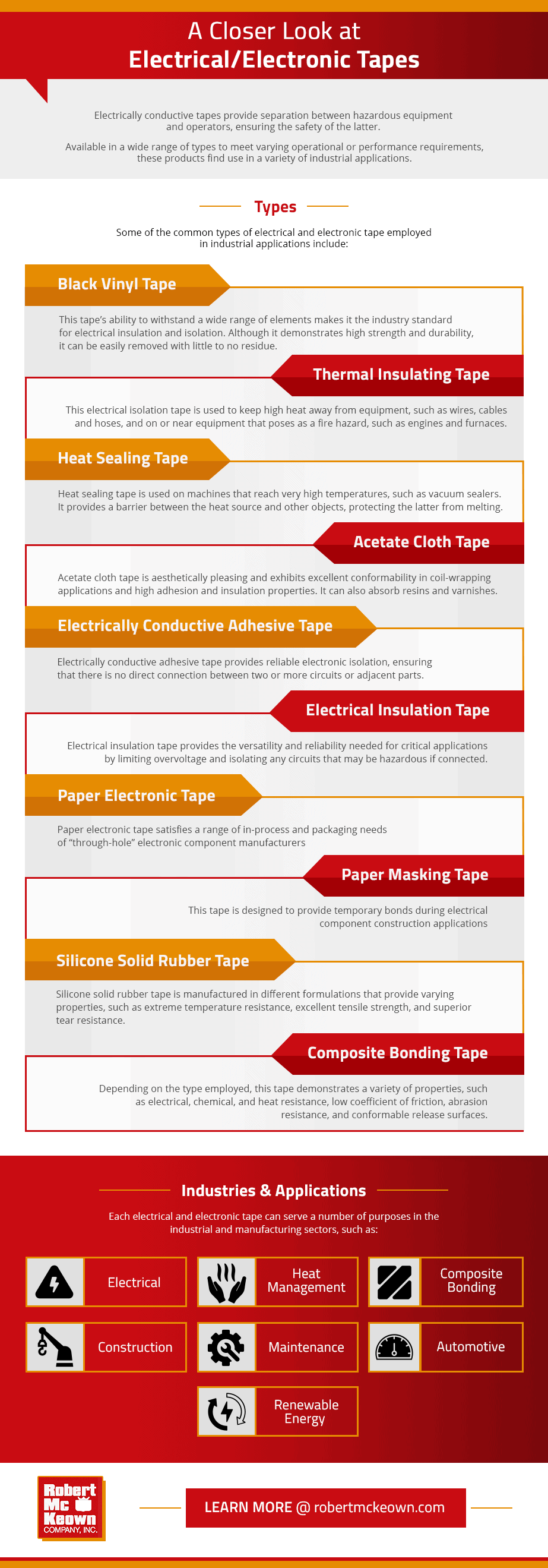

Electrically conductive tapes provide separation between hazardous equipment and operators, ensuring the safety of the latter. Available in a wide range of types to meet varying operational or performance requirements, these products find use in a variety of industrial applications.

TYPES OF TAPES

- Black Vinyl Tape: This tape’s ability to withstand a wide range of elements makes it the industry standard for electrical insulation and isolation. Although it demonstrates high strength and durability, it can be easily removed with little to no residue. It also exhibits excellent UV resistance.

- Thermal Insulating Tape: This electrical isolation tape is used to keep high heat away from equipment, such as wires, cables, and hoses, and on or near equipment that poses as a fire hazard, such as engines and furnaces. When heated, it becomes sticky, giving the tape greater adhesive flexibility. Cooling the tape allows for easy repositioning or removal of parts during assembly.

- Heat Sealing Tape: Heat sealing tape is used on machines that reach very high temperatures, such as vacuum sealers. It provides a barrier between the heat source and other objects, protecting the latter from melting.

- Acetate Cloth Tape: Acetate cloth tape is aesthetically pleasing and exhibits excellent conformability in coil-wrapping applications and high adhesion and insulation properties. It can also absorb resins and varnishes.

- Electrically Conductive Adhesive Tape: Electrically conductive adhesive tape provides reliable electronic isolation, ensuring that there is no direct connection between two or more circuits or adjacent parts. This tape is used in many industries, including electrical, medical, and pharmaceutical, for a variety of purposes.

- Electrical Insulation Tape: Electrical insulation tape provides the versatility and reliability needed for critical applications by limiting overvoltage and isolating any circuits that may be hazardous if connected.

- Paper Electronic Tape: Paper electronic tape satisfies a range of in-process and packaging needs of “through-hole” electronic component manufacturers. It is used in applications such as banding coils, coverings bobbin-wound coils, and end-turn taping.

- Paper Masking Tape: This tape is designed to provide temporary bonds during electrical component construction applications. It is also used in die-cutting operations.

- Silicone Solid Rubber Tape: Silicone solid rubber tape is manufactured in different formulations that provide varying properties, such as extreme temperature resistance, excellent tensile strength, and superior tear resistance.

- Composite Bonding Tape: Depending on the type employed, composite bonding tape demonstrates a variety of properties, such as electrical, chemical, and heat resistance, low coefficient of friction, abrasion resistance, and conformable release surfaces.

INDUSTRIAL USES FOR ELECTRICAL AND ELECTRONIC TAPE

Each electrical and electronic tape can serve a number of purposes in the industrial and manufacturing sectors, such as:

ELECTRICAL

Within the electrical industry, electrical and electronic tapes perform several functions. Typical functions include serving as protective jacketing for high-voltage cables and wire harnesses, providing electrical insulation, wrapping, sealing, and insulating cables to protect the equipment and operators, masking circuit boards components, and serving as wire labeling for safety.

HEAT MANAGEMENT

Electrical and electronic tapes provide thermal management in a variety of industrial applications. They help keep heat within a reasonable temperature range for the equipment.

COMPOSITE BONDING

Composite bonding tapes allow engineers to meet specific performance requirements by providing strength and reliability in critical applications. They allow for the bonding of dissimilar materials—such as metals, glass, rubber, and fiber-reinforced composites—to allow for a combination of advantageous characteristics in the overall system.

CONSTRUCTION

Within the construction and building industry, electrical and electronic tapes allow for greater design flexibility, higher strength bonds, and faster operations. For some applications, they can replace fasteners such as screws and rivets.

MAINTENANCE

Tapes are used to facilitate a variety of maintenance tasks, including repairs, painting, and marking safety areas.

AUTOMOTIVE

Typical applications of electrical and electronic tape in the automotive industry include:

- Mounting attachment parts

- Wire harnessing

- Cable mounting

- Mirror assembly

- Permanent paint protection

- Surface protection

RENEWABLE ENERGY

Adhesive tapes facilitate the production of a variety of renewable energy equipment from start to finish. For example, electrical tape provides frame bonding and permanent edge protection for solar panels. Additionally, during the manufacture of wind tube blades, tape can be used for mold preparation, lay-up and infusion, and permanent application on the finished blade.

LEARN MORE ABOUT ELECTRICALLY CONDUCTIVE TAPES AT RMK

At Robert McKeown Co., Inc., we specialize in electrically conductive tapes and films for industrial applications. Since 1937, our team has been dedicated to innovating and maintaining open communication with clients to deliver high-quality solutions tailored to their unique needs.

Regardless of whether you need next-day availability, fast-track quotes, or express and next-day samples and prototypes, we can fulfill the requirements of your project. To learn more about how our electronic tapes and adhesives can benefit your next project, contact us, or request a quote.