Category Archive: Uncategorized

Advantages of RTV Sealant

RTV sealants, or Room Temperature Vulcanizing sealants, are crucial in the world of electronic assembly. These sealants offer a range of benefits that enhance the durability and performance of electronic components. Robert McKeown, a renowned distributor and fabricator of high-performance materials, provides a diverse selection of RTV sealants designed to meet various industry needs. Here’s an overview of why RTV sealants are essential and stand out.

Advantages of RTV Sealants

Here are some RTV sealant advantages:

- Moisture Cure Technology: RTV sealants cure at room temperature when exposed to moisture. This technology allows for ease of application and a reliable curing process without the need for external heat or pressure.

- High Temperature Resistance: Many RTV sealants can withstand extreme temperatures, ensuring that electronic components remain sealed and protected even in high-temperature environments. This resistance is one of the crucial RTV sealant advantages for maintaining the integrity of electronic assemblies.

- Exceptional Adhesion: RTV sealants bond effectively to various surfaces, including metals, plastics, and ceramics. This strong adhesion is vital for components to stay in place and function as intended, which is another major RTV sealant advantage.

- Nonflow and Non-Sag Properties: Another RTV sealant advantage is the nonflow characteristic which ensures they stay in place after application, making them ideal for vertical and overhead uses.

- Chemical Resistance: RTV sealants are resistant to a wide range of chemicals and environmental factors like moisture, oils, and solvents. This chemical resistance is a key reason why RTV sealant uses are widespread in industries requiring durable protection for electronic components.

- Electrical Insulation: RTV sealants provide excellent electrical insulation, helping to prevent short circuits and other electrical issues. This feature ensures reliability in various RTV sealant uses, especially in electronics.

- Ease of Application and Fast Curing Options: The application of RTV sealants is straightforward, and some products offer fast tack properties for quicker assembly. This ease of use is another great advantage in the wide range of RTV sealant uses, allowing for improved production efficiency.

Robert McKeown offers a range of RTV sealants designed to meet diverse application needs. These sealants provide reliable performance in various conditions, ensuring strong adhesion and effective sealing. Whether you require quick setting or high durability, their selection addresses a wide array of RTV sealant uses across different industries.

Applications Across Various Industries

RTV sealants are essential across various industries due to their versatile properties.

In the electronics sector, RTV sealants ensure reliable performance in electronic assemblies, offering circuit protection and assisting with thermal management. For the healthcare industry, RTV sealant uses include safeguarding medical devices from harmful chemicals while providing safe solutions for skin contact applications. In the automotive field, they endure extreme weather and high temperatures, making them ideal for various automotive uses.

RTV sealants used in the aerospace industry benefit by protecting components from electromagnetic interference (EMI) and harsh environmental conditions. In robotics, RTV sealants enhance performance and durability by reducing EMI and providing effective sealing, which is another RTV sealant advantage.

For industrial machinery, RTV sealants boost productivity and shield equipment from electromagnetic interference, ensuring smooth operation. Finally, in technology and automation, RTV sealants support the reliable functionality of smart devices and automation systems, further demonstrating the broad scope of RTV sealant uses across various sectors.

Seal Smart, Seal Strong with Robert McKeown

At Robert McKeown, we offer a wide range of high-quality RTV sealants for your specific needs. Contact us today to learn more about our products and how they can benefit your applications or request a quote. Our team is ready to provide expert guidance and support to help you find the perfect solution. Don’t wait—reach out now and ensure your systems are protected and performing at their best!

What is Electromagnetic Interference?

Understanding what electromagnetic interference (EMI) means is essential to the safety and efficiency of countless electrical devices we rely on daily. This invisible yet pervasive force has many adverse effects that can interrupt, degrade, or even stop electronic devices and systems from performing as intended.

If you want to know what EMI is, we’ll explore what causes it, its potential impact, and some prevention techniques involved in shielding your devices against it. Through an in-depth look at these topics, you become equipped with the necessary knowledge to protect your electrical components from harmful EM interference.

Electromagnetic Interference At A Glance

EMI is the disturbance or unwanted noise affecting an electrical path in electrical devices and communication systems caused by external electromagnetic fields. This disruption can cause these devices to malfunction and operate poorly. Frequently, it will interfere with the transmission of signals, produce errors, and generate data corruption in digital devices.

Constant exposure of devices to EM interference will cause their circuits to degrade over time. It might also stop it from working altogether. Regarding data path, the negative impacts range from an increase in error rate to a total loss of data.

What Can Cause Electromagnetic Interference (EMI)?

Many factors cause EM interference, mainly due to the close relationship between electricity and magnetism. All electrical flow produces a small magnetic field, and a moving electrical field produces an electrical current. Therefore, high-powered electrical sources can affect susceptible electronic devices with EMI.

EMI is caused by many things, so it may also be caused by man-made and natural sources. Examples include:

- Ignition systems from internal combustion systems

- Cellular networks from mobile phones

- Northern and Southern lights

- Solar flares

- Atmospheric electrical phenomena and lightning

- Radio jamming

- Near-field communication

- Transmission from televisions

- Satellites and AM/FM radio

- Airport radar

- Electrical contacts, motor bushes, and arc welders

- White noise

The causes listed will generate changes in electrical currents and voltages, triggering electromagnetic interference in electronic devices. The electrical noise caused by these activities can disrupt the normal functioning of the devices, which is why utilizing EMI protection techniques is vital to prevent them from failing.

How To Deal With Electromagnetic Interference

The best way to prevent EM interference is by purchasing superior quality electronics tested against emission standards to ensure they don’t cause excessive EMI against other devices. Depending on the device affected and the source, EMI can be treated in various ways. Fortunately, there are plenty of options available for you to deal with it successfully.

Some of these prevention techniques include:

- Keep electronic devices away from heavy machinery

- Utilize shielded cables

- Encasing the circuits inside sealed enclosures made with copper, steel, or aluminum

- Employ high-quality passive EMI filters

- Use a snubber network between two contacts

- Multiple grounding points on an extensive ground plane

- Isolate circuits from ground loop voltages

- Separate grounds for analog and digital circuits

EM interference filters are commonly used to reduce EMI effects in inverters. These are generally employed in the input and output side of inverters. To protect circuits against EMI, consider using materials that can eliminate the source of noise. You can also upgrade the receiving device and check the coupling channel between the source and receptor. Finally, shielded cables are ideal for protecting devices against capacitively coupled interference.

EMI Services From Robert McKeown

The growing number of wireless devices and our increasing dependence on technology mean the exponential inflation of EM interference in our daily lives. Therefore, it’s crucial to know what causes it so that you can employ the proper prevention techniques to ensure the safety and efficiency of your electronic devices.

At Robert McKeown, we design and develop high-performance EM interference shielding products to prevent EMI’s devastating consequences on your electronics. From EMI gaskets to tapes, we have the perfect solution to meet your needs. Contact us today for more information about our offers, and you can also request a quote for a cost-effective solution based on your project’s requirements!

Properties of Various Thermal Interface Materials

What Are Thermal Interface Materials?

Chips in electronic devices can generate a lot of heat during operation, which can damage fragile internal components. But thermal interface materials, or TIMs, can protect them by dissipating the heat and transferring it away from the internal configuration. TIMs are manufactured from a wide range of materials to align with the needs of different electronic devices, and they often sit between the chips and any internal heat-dissipating systems.

Chemical Composition of Thermal Interface Materials

Depending on the unique needs and characteristics of specific electronic devices, manufacturers can choose from a wide range of thermal interface materials with different chemical compositions. Here are the most common options.

Epoxy Resins

Epoxy resins are materials that can be poured and shaped as a liquid before setting or curing into a hardened material with exposure to heat. This process is called thermosetting. Epoxy compounds are made from monomers with two or more epoxide groups. Some of the key benefits of using an epoxy resin as a TIM are:

- Specialized properties based on the unique chemical structure and the specific epoxides in the compound

- Good adhesive strength

- Resistance to chemicals

Polyvinyl Chloride (PVC)

Called polyvinyl chloride, vinyl, or PVC, these compounds are a type of polymer. They are at least 50% chlorine by weight and are primarily made up of vinyl chloride monomers, which polymerize during the fabrication process.

Polycarbonate (PC)

These thermoplastics are defined by the carbonate groups present in their chemical composition. There is a wide variety of different polycarbonate grades or types. Polycarbonate TIMs possess these key characteristics:

- Varying degrees of transparency

- High levels of strength

- Toughness and resistance to physical damage

Polypropylene (PP)

A popular type of thermoplastic TIM is polypropylene (PP). Manufacturers can fabricate the material from propylene monomers through chain-growth polymerization processes.

Each of these materials—epoxy resins, PVC, polycarbonate, or polypropylene—can be used as thermal interface materials. An experienced TIM manufacturing provider can help advise you on the right fit for your specific project.

Thermal Interface Material Product Applications

TIMs can help protect electronics in a range of consumer, commercial, and industrial systems. When temperatures get too high, whether it’s in small handheld devices or large industrial systems, the parts can overheat, wear through faster, and deliver subpar performance. Some of the applications that most rely on cutting-edge TIM options are telecommunications, aerospace, automotive, gaming, and servers.

Thermal interface materials come in a variety of forms to fit these industrial applications.

Greases

TIMs don’t just have to be solid products. They can also be hydrocarbon or silicone thermal greases that contain fillers to optimize their thermal dissipation capabilities. TIM greases help remove microscopic air pockets that hold heat.

Elastomeric Pads

Elastomeric pads are very thin but solid TIMs. Each one is approximately 0.25 mm thick and constructed from a woven fiberglass substrate with polymerized silicone rubber and filler additives built in. The silicone rubber and fillers act similarly to greases, while the woven piece gives the pad structure. Assemblers add them as precise, die-cut forms to electronic configurations during production.

Thermal Tapes

Functioning as a heat sink, thermal tapes absorb and disperse heat, but they also have adhesive surfaces to ensure the heat sink stays locked in place in its electronic assembly. This reduces space and hardware requirements for the heat sink. The basic structure of a thermal tape is a structural support matrix such as a foil strip, fiberglass mat, or polyimide film with a pressure-sensitive adhesive coating.

Phase Change Materials

As the name implies, phase change materials have the properties of both liquid greases and structurally solid pads. Since their development in the 1980s and quick rise to popularity throughout the following decade, phase change materials have been used for microprocessors and other precision assemblies where liquid grease poses too much of a complication.

TIMs (Thermal Interface Materials) by Robert McKeown

Choosing the right thermal interface materials can make your electronics last longer with less risk of damage or poor performance. At Robert McKeown, we develop cutting-edge, versatile, and precision TIMs, including TIM thermal pastes, phase change pads, double-sided tapes, and more. Request a quote today to discuss your specific thermal interface material needs.

Benefits of Potting Electronics

To provide electronic components with sufficient protection against an array of hazards, many fabricators use a process called potting. By potting electronics, you better safeguard electronic wiring, parts, and devices from premature failure so as not to compromise electronic systems. Learn more about potting in electronics, how it works, and its benefits and applications.

What Is Potting in Electronics?

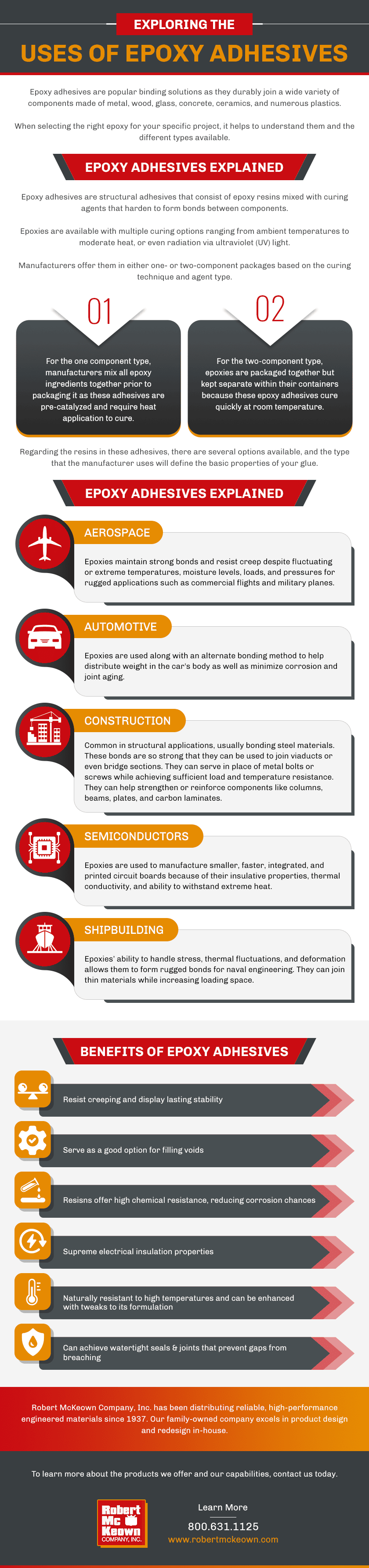

Exploring the Uses of Epoxy Adhesives

Epoxy adhesives are popular binding solutions as they durably join a wide variety of components made of metal, wood, glass, concrete, ceramics, and numerous plastics. To select the right epoxy for your specific project, it helps to understand them and the different types available. Read on to learn about epoxy uses and the advantages these adhesives offer diverse applications.

Epoxy Adhesives Explained

Structural Adhesives for Aerospace Applications

Conformal Coatings: A Comprehensive Guide

Conductive Tapes – A Selection Guide

Conductive tapes are flexible adhesives that conduct current on one or both sides. These tapes are a useful and cost-effective option for electronic assembly, especially in shielding or grounding applications.

Conductive tape offers many advantages over other assembly methods such as soldering or mechanical fastening. Tapes are flexible, easy to apply, and offer better performance in settings with extreme temperatures or frequent vibrations.

At Robert McKeown Company, we offer a full range of conductive tapes for clients seeking these benefits for their electronic assemblies. As a long-time supplier of high-performance electronics materials, we can work with you to determine the best adhesive tape solution for your needs.

CONDUCTIVE TAPE TYPES

Conductive tapes can be classified in several ways:

- Conductive Adhesive vs. Non-Conductive Adhesive. Tapes with conductive adhesive conduct electricity on both the top and the bottom. The polymers that make these tapes sticky contain tiny, embedded metal particles that conduct current. By contrast, some conductive tapes do not have these embedded components, so they only conduct current on the non-adhesive surface.

- Isotropic vs. Anisotropic. Isotropic tapes conduct current in every direction while anisotropic adhesives conduct along only one axis.

- Material. Conductive tapes can be made from many different materials, including copper, aluminum, and conductive alloys.

Robert McKeown Company offers performance CHO-FOIL tapes in several material options with conductive and non-conductive adhesives:

- Copper Foil Tape. Copper is highly desirable for electrical applications because of its excellent conductivity, which is second only to silver. Copper is a particularly good choice for both grounding and shielding applications because it reliably blocks both magnetic and electrical waves for maximum performance.

- Aluminum Foil Tape. Although its conductivity is slightly lower than copper’s, aluminum tapes offer excellent electrical performance and shielding characteristics. Aluminum tape also tends to be more cost-effective than copper or tinned copper tapes.

- Tinned Copper Foil Tape. Tinned copper foil has similar electrical properties to copper foil, but the tin content makes the tape more resistant to humidity and extreme temperatures. Unlike unalloyed copper, tinned copper won’t oxidize in these more difficult environments, so it is a better choice if durability is a concern.

Before purchasing conductive tape, it’s important to understand these distinctions to ensure you get the results you’re expecting.

COMMON APPLICATIONS FOR CONDUCTIVE ADHESIVES

Conductive tapes have many uses, but the most common involve shielding and grounding. For instance, they are often used to attach EMI and RFI shields to electronic devices. They can also be used to pass current to substrates that cannot be soldered or to create corrosion-resistant ground contacts, among other applications.

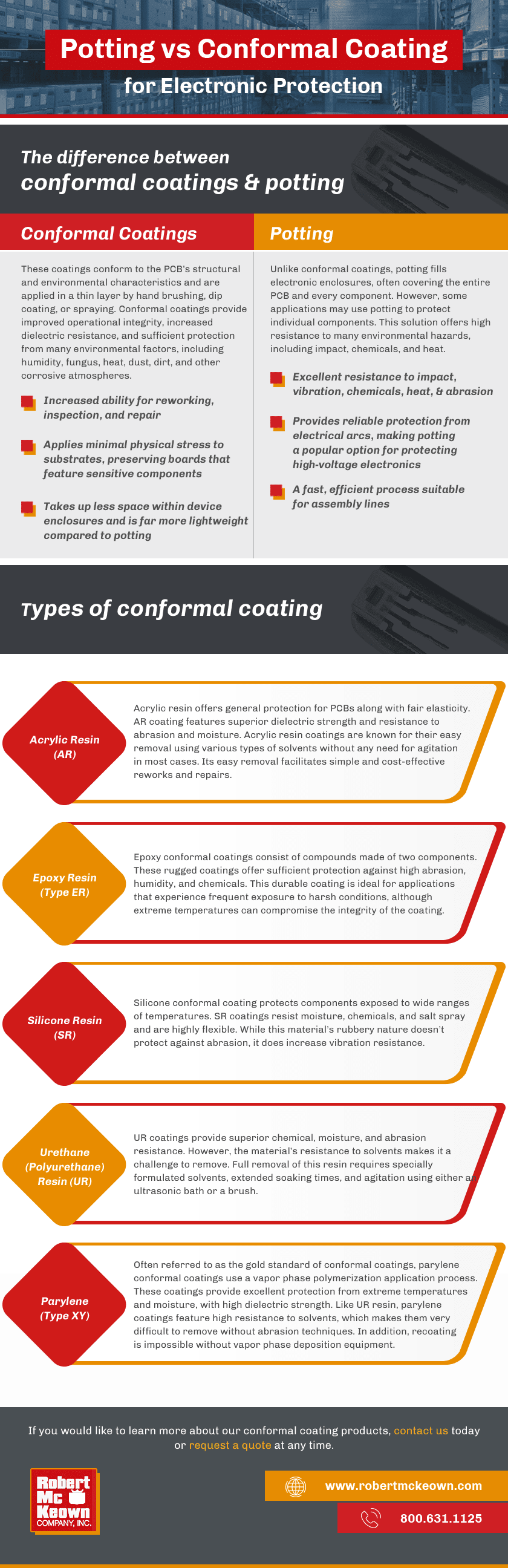

Potting vs Conformal Coating for Electronic Protection

Electronic components, including printed circuit boards (PCBs), often sustain damage and wear as a result of exposure to harsh environments. Conformal coatings offer protection for these components from a variety of potentially damaging environmental factors, including dust, moisture, chemicals, and salt, along with mechanical abrasion and changes in temperature. With the help of reliable conformal coating, electronics won’t be susceptible to corrosion and other types of damage.

The Difference Between Conformal Coatings & Potting

Both potting and conformal coatings protect PCBs and other electronic components but differ in functionality and application. The following are the key differences between these two types of protective materials:

Conformal Coatings

These coatings conform to the PCB’s structural and environmental characteristics and are applied in a thin layer by hand brushing, dip coating, or spraying. Conformal coatings provide improved operational integrity, increased dielectric resistance, and sufficient protection from many environmental factors, including humidity, fungus, heat, dust, dirt, and other corrosive atmospheres.

Some of the advantages of using conformal coatings include:

- Increased ability for reworking, inspection, and repair

- Applies minimal physical stress to substrates, preserving boards that feature sensitive components

- Takes up less space within device enclosures and is far more lightweight compared to potting

Potting

Unlike conformal coatings, potting fills electronic enclosures, often covering the entire PCB and every component. However, some applications may use potting to protect individual components. This solution offers high resistance to many environmental hazards, including impact, chemicals, and heat.

Potting offers a few key benefits, such as:

- Excellent resistance to impact, vibration, chemicals, heat, and abrasion

- Provides reliable protection from electrical arcs, making potting a popular option for protecting high-voltage electronics

- A fast, efficient process suitable for assembly lines

Types of Conformal Coating

Depending on the needs of the application, there are several types of conformal coating materials available, including:

Acrylic Resin (AR)

Acrylic resin offers general protection for PCBs along with fair elasticity. AR coating features superior dielectric strength and resistance to abrasion and moisture. Acrylic resin coatings are known for their easy removal using various types of solvents without any need for agitation in most cases. Its easy removal facilitates simple and cost-effective reworks and repairs.

Epoxy Resin (Type ER)

Epoxy conformal coatings consist of compounds made of two components. These rugged coatings offer sufficient protection against high abrasion, humidity, and chemicals. This durable coating is ideal for applications that experience frequent exposure to harsh conditions, although extreme temperatures can compromise the integrity of the coating.

Silicone Resin (SR)

Silicone conformal coating protects components exposed to wide ranges of temperatures. SR coatings resist moisture, chemicals, and salt spray and are highly flexible. While this material’s rubbery nature doesn’t protect against abrasion, it does increase vibration resistance.

Urethane (Polyurethane) Resin (UR)

UR coatings provide superior chemical, moisture, and abrasion resistance. However, the material’s resistance to solvents makes it a challenge to remove. Full removal of this resin requires specially formulated solvents, extended soaking times, and agitation using either an ultrasonic bath or a brush.

Parylene (Type XY)

Often referred to as the gold standard of conformal coatings, parylene conformal coatings use a vapor phase polymerization application process. These coatings provide excellent protection from extreme temperatures and moisture, with high dielectric strength. Like UR resin, parylene coatings feature high resistance to solvents, which makes them very difficult to remove without abrasion techniques. In addition, recoating is impossible without vapor phase deposition equipment.

Conformal Coatings at Robert McKeown Company, Inc.

Conformal coatings help protect PCBs from many types of hazardous environments, maximizing their longevity. At Robert McKeown Company, Inc., we offer custom conformal coating solutions based on our clients’ unique requirements. Our experts will help select the right materials for your electronic components to meet any specifications.

If you would like to learn more about our conformal coating products, contact us today or request a quote at any time.

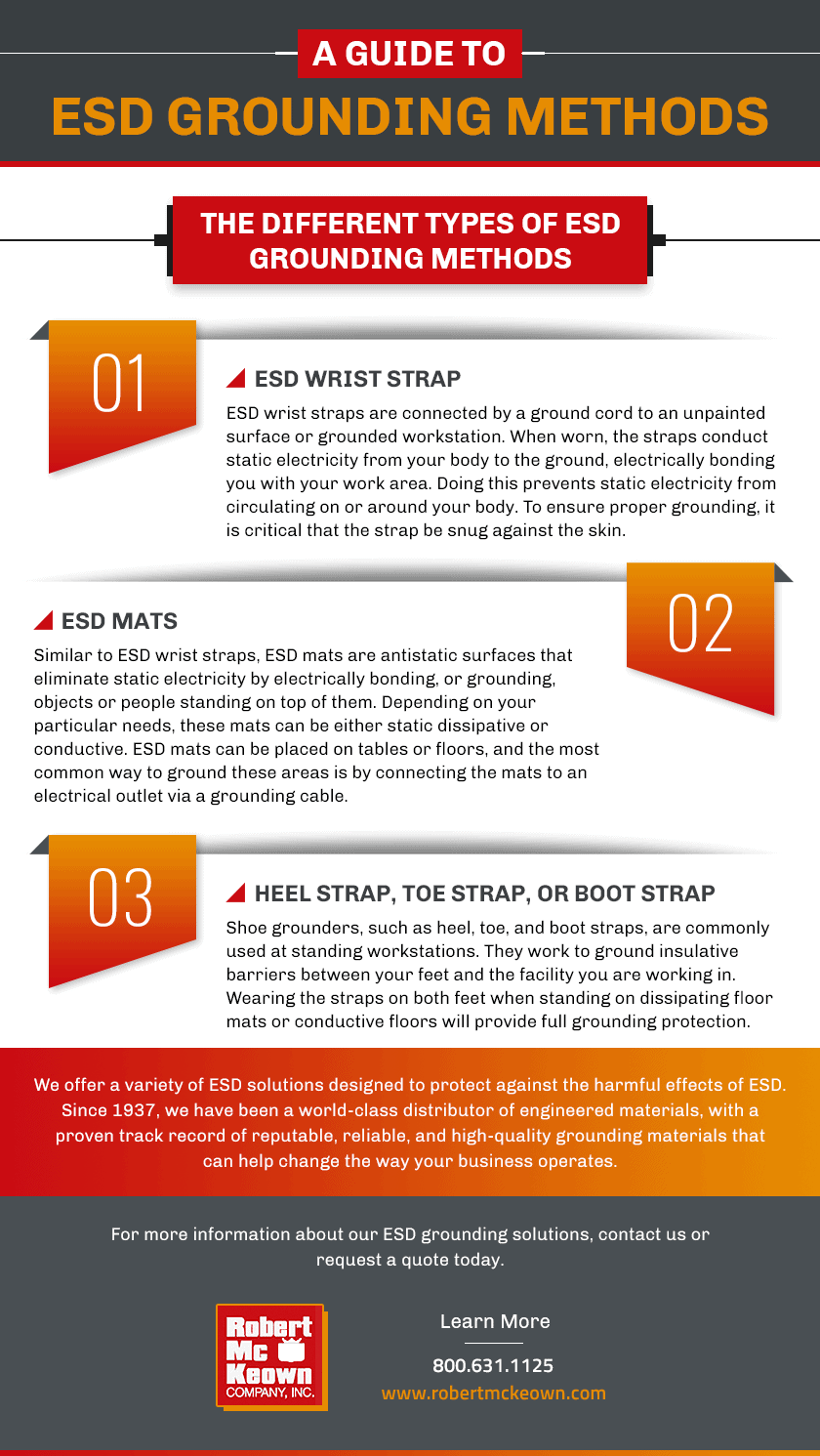

A Guide to ESD Grounding Methods

In an ever-so technological world, working with highly sensitive electronic devices has become increasingly common across a range of businesses. With that comes certain dangers, such as electrostatic discharge (ESD). ESD refers to the sudden flow of electricity between two electrically charged objects caused by instances such as a short or breakdown.

ESD poses life-threatening dangers to workers; therefore, it is crucial to implement the proper ESD grounding methods. ESD grounding not only improves workplace safety but it’s also an important component of static control.

Developing ESD Grounding Requirements

Developing a widespread policy on how employees should ground themselves while working can be an invaluable step in boosting workplace safety and preventing product damage. Determining ESD grounding requirements for your facility depends on where grounding is needed. The policy could cover areas such as work benches, manufacturing floors, packing and shipping centers, research and development labs, clean rooms, and more.

Other key factors to consider when determining the ESD grounding requirements of a facility include the type of work taking place and the size of the workspace. For example, smaller companies can typically follow basic ESD grounding requirements while larger companies may need to implement stricter guidelines.

The Different Types of ESD Grounding Methods

There are several ESD grounding methods companies can use to protect products and personnel. Implementing the following precautions ensures worker safety when installing or handling electrostatic-sensitive devices:

ESD Wrist Strap

ESD wrist straps are connected by a ground cord to an unpainted surface or grounded workstation. When worn, the straps conduct static electricity from your body to the ground, electrically bonding you with your work area. Doing this prevents static electricity from circulating on or around your body. To ensure proper grounding, it is critical that the strap be snug against the skin.

ESD Mats

Similar to ESD wrist straps, ESD mats are antistatic surfaces that eliminate static electricity by electrically bonding, or grounding, objects or people standing on top of them. Depending on your particular needs, these mats can be either static dissipative or conductive. ESD mats can be placed on tables or floors, and the most common way to ground these areas is by connecting the mats to an electrical outlet via a grounding cable.

Heel Strap, Toe Strap, or Boot Strap

Shoe grounders, such as heel, toe, and boot straps, are commonly used at standing workstations. They work to ground insulative barriers between your feet and the facility you are working in. Wearing the straps on both feet when standing on dissipating floor mats or conductive floors will provide full grounding protection.

Prioritize ESD Grounding with Robert McKeown Inc.

Implementing proper ESD grounding techniques doesn’t have to be a hard and complicated process. With the simple methods outlined above, companies of any size and specialization can work towards a safer work environment for their employees.

Robert McKeown can help with exactly that! We offer a variety of ESD solutions designed to protect against the harmful effects of ESD. Since 1937, we have been a world-class distributor of engineered materials, with a proven track record of reputable, reliable, and high-quality grounding materials that can help change the way your business operates.

For more information about our ESD grounding solutions, contact us or request a quote today.