Category Archive: Henkel

Henkel Adhesives Deliver for Wearable Electronics

From smart watches to user interface glasses, wearable electronics are on the edge of technology allowing consumers to take their smart gadgets on the go. As the demand for mobility rises, devices get smaller and the technology to manufacture them continues to advance and evolve. The rigorous demands of wearable electronics are keeping adhesive technology at the forefront of innovation.

HENKEL ADHESIVES PROVIDE HIGH-PERFORMANCE SOLUTIONS

Wearable electronics demand requires performance and reliability under the most adverse conditions. Exposure to shock, stress, vibration, extreme temperatures, and water/moisture can’t be allowed to affect performance and reliability. In this rapidly growing market where less is more, there is no place for bulky adhesive products on devices where size and limitations are crucial. Manufacturers of wearable technology depend on Henkel for the adhesive solutions they need to take their complex products from the design table to the production line.

Continue reading

Loctite Ablestik SSP 2020

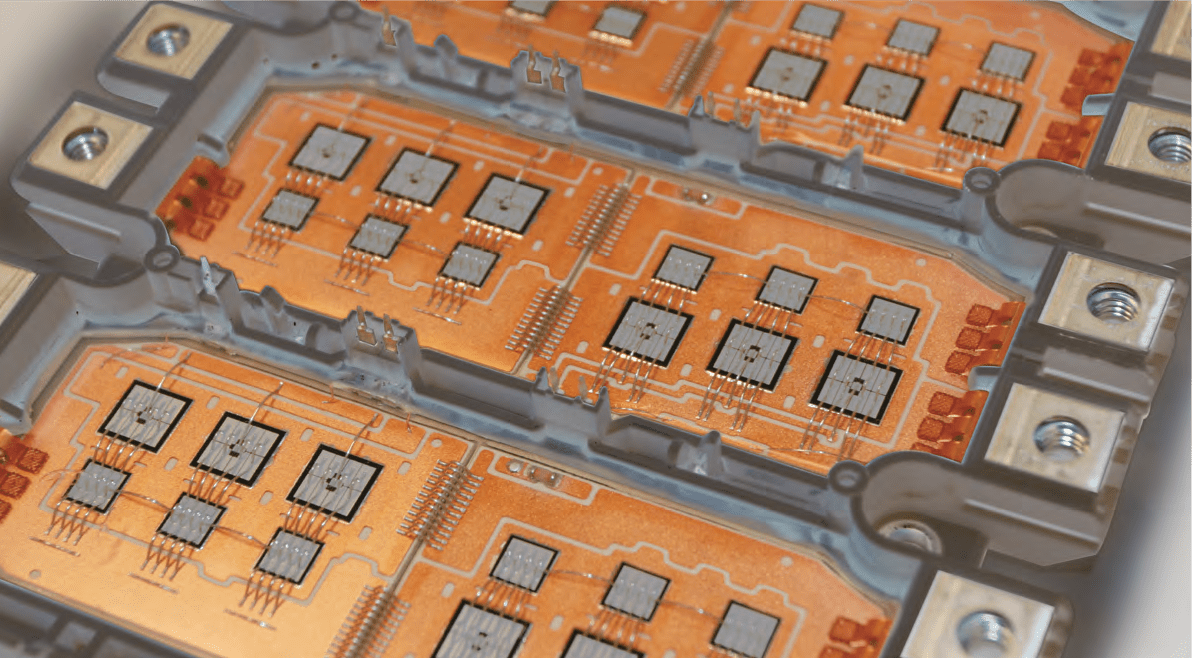

LOCTITE introduces ABLESTIK SSP 2020. An Ag-based material that delivers a robust intermetallic bond between targeted surfaces, the substrate and die, via a pressureless or pressure sintering process. This solution, ideal for high power devices, facilitates much higher thermal and electrical conductivity than traditional die attach adhesives and has performance equivalent or better than solder — all while meeting the stringent requirements of lead-free legislation. The technical staff at the Robert McKeown Company is available to assist you with integration of SSP 2020 into your manufacturing process.

LOCTITE ABLESTIK SSP 2020 is a sintering silver paste die attach adhesive designed for devices requiring elevated thermal and electrical conductivity capabilities. It is formulated to provide high heat transfer generated from power devices. It maintains high adhesion at operating temperatures as high as 260°C. It is stencil printable and syringe dispensable.

- Ideal for high power devices

- Delivers a robust intermetallic bond between targeted surfaces

- Facilitates much higher thermal and electrical conductivity than traditional die attach adhesives

- Provides strong adhesion

- Compatible with current production equipment, high throughput

- 10x thermal cycle & power cycle performance better than solder

Henkel Loctite GC10

Henkel Loctite GC10 is the industry’s first temperature stable solder paste. GC10 is stable at 26.5 degrees Celsius for one year and at temperatures of up to 40 degrees Celsius for one month. This temperature stability provides tremendous benefits throughout the logistics and operations chain.

Click here to download a PDF copy of the Henkel Loctite Game Changer 10 Specifications

In production, Henkel Loctite GC10 offers huge improvements over conventional solder pastes in printed circuit board assembly. As compared to traditional materials which average abandon times from 1 to 4 hours, this halogen-free, lead-free, temperature-stable formula enables abandon time of up to 24 hours and has a startup time of zero. Stabilized and consistent print transfer efficiency, an expanded reflow window and increased activity for better results with soak temperatures between 150 degrees C and 200 degrees C, make Henkel Loctite GC10 incomparable among solder pastes. And, GC10’s dependability on the line yields material utilization of over 95%.

By using Henkel Loctite GC10 the Robert McKeown Company offers its customers both process improvements and cost reductions. The temperature stability of this product will eliminate the challenges with shipping and storage. GC10 is setting a new standard for high performance solder materials with improvements in production, higher yields and ultimately better profitability.

For a sample of Henkel Loctite GC10 or to speak with a technical specialist call 800.631.1125 or email sales@robertmckeown.com

Continue reading