Category Archive: Products

How Do EMI Gaskets Work to Protect Your Equipment?

When it comes to the world of electronic equipment, one undesirable element that’s sometimes found in electrical setups is known as electromagnetic interference (EMI). EMI can have a negative effect on performance and lifespan of various kinds of electrical equipment, but there are also several approaches you can take to avoid this issue – and one of the most robust is the use of what are known as EMI gaskets.

For almost 100 years, Robert McKeown has served as a leading manufacturer and distributor of high-quality materials for electronic assembly, including EMI shielding gaskets and gasket tape products. What are EMI gaskets, how do EMI gaskets work, and which types of EMI gaskets and gasket applications are out there? Let’s dive into a full exploration of these important components.

What Are EMI Shielding Gaskets?

Many of our readers will be familiar with standard gaskets, which are meant to create a seal between two surfaces to block things like air, water or other materials from entering the seal. EMI gaskets have a similar purpose, but with a very different medium: They are meant to block out interference from potentially damaging technology.

In todays’ day and age, with so many electronic devices available and being utilized virtually everywhere, electronic interference is common. There are two primary types of interference to know about:

- Electromagnetic interference (EMI): As we referenced above, EMI is caused by electromagnetic fields, which are generated by things like radios, motors or power lines.

- Radio frequency interference (RFI): RFI is created when radio waves are emitted from sources such as cell phones, wireless networks and other equipment.

EMI shielding gaskets are made primarily to deal with EMI, though many can also handle RFI to some extent.

How Do EMI Gaskets Function?

Diving under the hood just a bit, EMI gaskets are made from various dampening materials like metal, wire mesh or various elastomers. These materials will be thick and/or conductive enough to block common electromagnetic waves and interference.

These materials are cut into shapes that cover the entire opening or surface of a given device area. They will often also be laminated with adhesive on either or both sides, ensuring they can block out signals from everywhere. Many EMI gaskets are available in standard sizes and can be purchased at hardware stores; others will be custom-made to fit specific appliances.

In actual application, the purpose of an EMI gasket is to form a conductive barrier between two surfaces, preventing electronic signals from reaching the inner workings of your device. They also serve as a physical seal that blocks out dust and other contaminants.

What EMI Gasket Types Are There?

EMI gaskets are available in several different types, including:

- Conductive elastomer EMI gaskets: These high-performance gaskets are made with silicone or another rubber elastomer, but often embedded with metallic components as well. Using pressure-sensitive adhesive, these can be applied to almost any surface and provide high levels of EMI shielding.

- Wire mesh EMI gaskets: These are made from incredibly tiny metal wires woven together at a right angle. The result is a fine grid that will block out RF signals.

- Beryllium copper EMI gaskets: Because of the high conductivity in copper, these gaskets are fantastic at blocking EMI or RFI. They need little compression and can work across a wide range of temperatures. These are some of the most popular options for custom-made gaskets.

There are also several EMI gasket types that involve conductive foams or tapes, which can be affixed to surfaces with adhesive. Some of these foams are low compression, making them perfect for thin applications that need a small amount of pressure for electrical connection. Tapes and foams are often made from conductive material like aluminum, copper or nickel-plated fabric; however, most EMI gasket materials use stainless steel as their primary conductor.

Gasket Applications

EMI gaskets have many different applications in the world of electronics, including:

- Computer applications: Whether to shield specific computer components from EMI due to nearby interference or to secure server racks, EMI gaskets are commonly used in the computer industry.

- Medical equipment: Many medical devices use EMI gaskets to keep their sensitive electronics shielded from interference that could cause malfunctions.

- Automotive controls: More and more vehicle manufacturers are adding computer and electronic systems within their vehicles. All of these components in such limited spaces can cause issues with EMI, but EMI gaskets are an effective fix.

- Aerospace applications: Many aerospace components, such as satellites and military equipment, require reliable EMI shielding to ensure proper operation and avoid interference from other systems.

- Smartphones and other high-level electronics: With the ever-increasing complexity and miniaturization of electronic devices, EMI gaskets are essential to prevent interference and extend the lifespan of these valuable pieces of technology.

EMI shielding gaskets play an important role in protecting electrical equipment from interference that can negatively impact performance and longevity. Knowing what type of EMI gasket is needed for your specific application is crucial, as well as understanding how they function and their various applications across different industries. By using high-quality EMI gaskets, you can ensure that your electronics operate at their full potential without disruptions or damage caused by interference.

The team at Robert McKeown is here to provide you with the best EMI gasket solutions for your needs. Contact us today for more information and to discuss which type of EMI gasket is right for your application. Let us help you protect your valuable electronic equipment from harmful interference.

Protect Your Equipment and Employees With Shielding Tapes

The effects of electromagnetic interference (EMI) and electrostatic discharge (ESD) can be devastating to sensitive electronic and electrical equipment and the employees that operate them. For example:

- EMI can ruin data collection and transmission, degrade signals, and interfere with or damage critical devices such as pacemakers.

- ESD can cause component failure and circuit destruction and result in electrical shock if the charge is not adequately dissipated.

Shielding products—such as shielding tapes—help disperse ESD and block EMI to minimize the risk of injury to life and limb and ensure the continued operation of the equipment. Shielding tapes act as a sealant. Instead of sealing in or out liquids, dirt, and other physical contaminants, they create a barrier that isolates the equipment and seals in or seals out EMI, ESD, and radio wave signals generated by environmental sources or the equipment itself.

Due to their critical function in electronic and electrical devices, shielding tapes find application in a wide range of industries, including medical and aerospace. Within these industries, companies employ EMI seals to protect their equipment and employees.

ADVANTAGES OF USING SHIELDING TAPE

When used in electronic and electrical systems for industrial applications, EMI shielding tape offers numerous advantages, including:

- Broader design flexibility and versatility. Shielding tapes are available in a variety of designs, materials, and sizes, which allows them to be tailored for use in a wide range of equipment and employee protection applications.

- Easier application and use. The application of EMI tape requires minimal surface preparation—i.e., ensuring the surface is dry and clean—and no specialized tools. As shielding tapes generally come with a pre-applied adhesive backing, they only require sufficient pressure to ensure adhesion to the equipment surface. As a grounding solution, the metallic part of the tape helps to disperse electrical charges safely without needing screws or other fasteners.

- Reduced crosstalk. Using these tapes reduces crosstalk—i.e., the interference of one signal by another nearby signal—across program or transmission channels.

- Greater protective properties. Shielding tapes minimize the adverse effects of ESD and ESI, resulting in greater protection for employees and equipment.

- Better durability. Many shielding tapes demonstrate superior abrasion and corrosion resistance and flame retardant properties, which enable them to withstand the stresses of use and result in longer service lives.

WHY WORK WITH SHIELDING TAPE EXPERTS?

With the numerous types of shielding tapes available, choosing the right one for a shielding application can be difficult. In these situations, it helps to get help. By consulting with an experienced fabricator and distributor of shielding tapes, customers receive qualified advice about which tape(s) is/are suitable for their needs or application and how best to apply it/them.

ORDER YOUR CUSTOM SHIELDING TAPES TODAY

Shielding products such as shielding tapes help protect your equipment and employees from EMI and ESD. At Robert McKeown, we offer shielding tapes and gaskets for use in industrial shielding applications. To further customize these EMI shielding products to our customers’ needs, we offer die cutting services.

To learn more about our EMI shielding tape and gasket offerings, contact us or request a quote.

Which Electrical/Electronic Tape Is Right for Your Application?

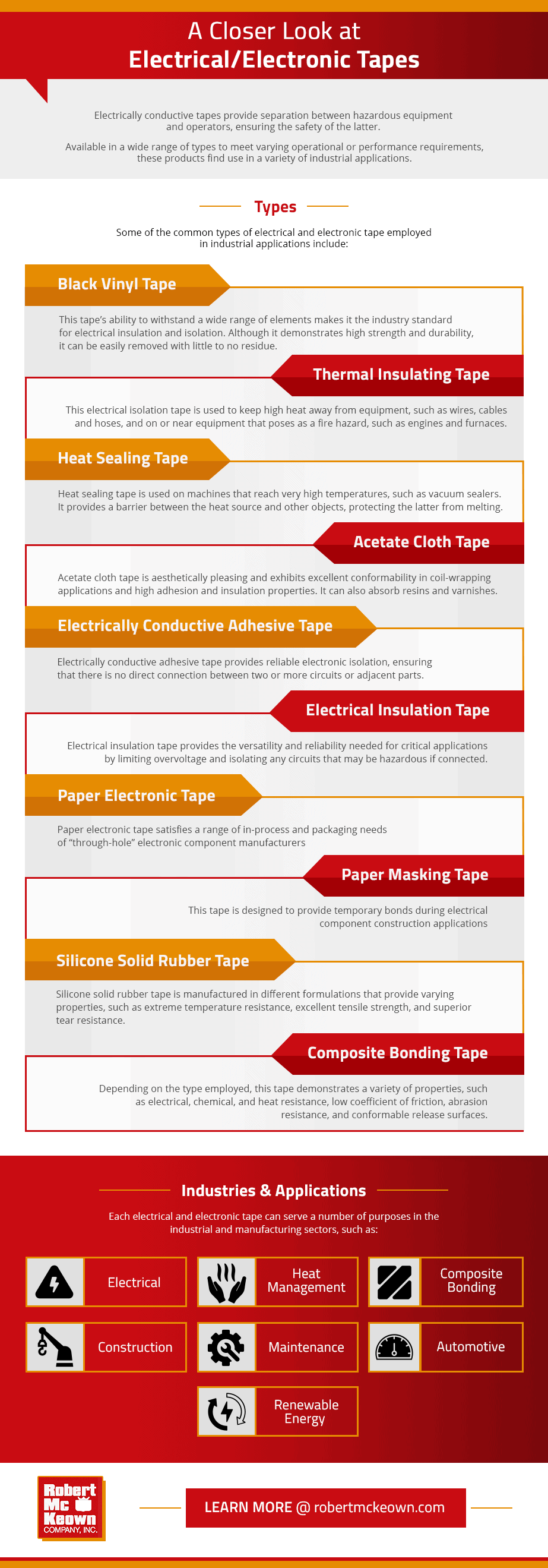

Electrically conductive tapes provide separation between hazardous equipment and operators, ensuring the safety of the latter. Available in a wide range of types to meet varying operational or performance requirements, these products find use in a variety of industrial applications.

TYPES OF TAPES

- Black Vinyl Tape: This tape’s ability to withstand a wide range of elements makes it the industry standard for electrical insulation and isolation. Although it demonstrates high strength and durability, it can be easily removed with little to no residue. It also exhibits excellent UV resistance.

- Thermal Insulating Tape: This electrical isolation tape is used to keep high heat away from equipment, such as wires, cables, and hoses, and on or near equipment that poses as a fire hazard, such as engines and furnaces. When heated, it becomes sticky, giving the tape greater adhesive flexibility. Cooling the tape allows for easy repositioning or removal of parts during assembly.

- Heat Sealing Tape: Heat sealing tape is used on machines that reach very high temperatures, such as vacuum sealers. It provides a barrier between the heat source and other objects, protecting the latter from melting.

- Acetate Cloth Tape: Acetate cloth tape is aesthetically pleasing and exhibits excellent conformability in coil-wrapping applications and high adhesion and insulation properties. It can also absorb resins and varnishes.

- Electrically Conductive Adhesive Tape: Electrically conductive adhesive tape provides reliable electronic isolation, ensuring that there is no direct connection between two or more circuits or adjacent parts. This tape is used in many industries, including electrical, medical, and pharmaceutical, for a variety of purposes.

- Electrical Insulation Tape: Electrical insulation tape provides the versatility and reliability needed for critical applications by limiting overvoltage and isolating any circuits that may be hazardous if connected.

- Paper Electronic Tape: Paper electronic tape satisfies a range of in-process and packaging needs of “through-hole” electronic component manufacturers. It is used in applications such as banding coils, coverings bobbin-wound coils, and end-turn taping.

- Paper Masking Tape: This tape is designed to provide temporary bonds during electrical component construction applications. It is also used in die-cutting operations.

- Silicone Solid Rubber Tape: Silicone solid rubber tape is manufactured in different formulations that provide varying properties, such as extreme temperature resistance, excellent tensile strength, and superior tear resistance.

- Composite Bonding Tape: Depending on the type employed, composite bonding tape demonstrates a variety of properties, such as electrical, chemical, and heat resistance, low coefficient of friction, abrasion resistance, and conformable release surfaces.

INDUSTRIAL USES FOR ELECTRICAL AND ELECTRONIC TAPE

Each electrical and electronic tape can serve a number of purposes in the industrial and manufacturing sectors, such as:

ELECTRICAL

Within the electrical industry, electrical and electronic tapes perform several functions. Typical functions include serving as protective jacketing for high-voltage cables and wire harnesses, providing electrical insulation, wrapping, sealing, and insulating cables to protect the equipment and operators, masking circuit boards components, and serving as wire labeling for safety.

HEAT MANAGEMENT

Electrical and electronic tapes provide thermal management in a variety of industrial applications. They help keep heat within a reasonable temperature range for the equipment.

COMPOSITE BONDING

Composite bonding tapes allow engineers to meet specific performance requirements by providing strength and reliability in critical applications. They allow for the bonding of dissimilar materials—such as metals, glass, rubber, and fiber-reinforced composites—to allow for a combination of advantageous characteristics in the overall system.

CONSTRUCTION

Within the construction and building industry, electrical and electronic tapes allow for greater design flexibility, higher strength bonds, and faster operations. For some applications, they can replace fasteners such as screws and rivets.

MAINTENANCE

Tapes are used to facilitate a variety of maintenance tasks, including repairs, painting, and marking safety areas.

AUTOMOTIVE

Typical applications of electrical and electronic tape in the automotive industry include:

- Mounting attachment parts

- Wire harnessing

- Cable mounting

- Mirror assembly

- Permanent paint protection

- Surface protection

RENEWABLE ENERGY

Adhesive tapes facilitate the production of a variety of renewable energy equipment from start to finish. For example, electrical tape provides frame bonding and permanent edge protection for solar panels. Additionally, during the manufacture of wind tube blades, tape can be used for mold preparation, lay-up and infusion, and permanent application on the finished blade.

LEARN MORE ABOUT ELECTRICALLY CONDUCTIVE TAPES AT RMK

At Robert McKeown Co., Inc., we specialize in electrically conductive tapes and films for industrial applications. Since 1937, our team has been dedicated to innovating and maintaining open communication with clients to deliver high-quality solutions tailored to their unique needs.

Regardless of whether you need next-day availability, fast-track quotes, or express and next-day samples and prototypes, we can fulfill the requirements of your project. To learn more about how our electronic tapes and adhesives can benefit your next project, contact us, or request a quote.

Adhesives and Sealants Designed for Electronics

Robert McKeown offers a variety of adhesive and sealant products for a wide range of commercial and industrial applications.

To learn more about our customizable adhesives and sealants, please contact us today.